EOS adds high-strength, anodisable aluminium alloy EOS Aluminium Al5X1

October 19, 2023

EOS, headquartered in Krailling, Germany, has added EOS Aluminium Al5X1 to the range of aluminium alloys that can be processed on its metal Additive Manufacturing machines. This alloy is specifically designed for Additive Manufacturing and is reported to offer provide excellent performance and material properties, with a tensile strength of approximately 410 MPa UTS and 14% elongation.

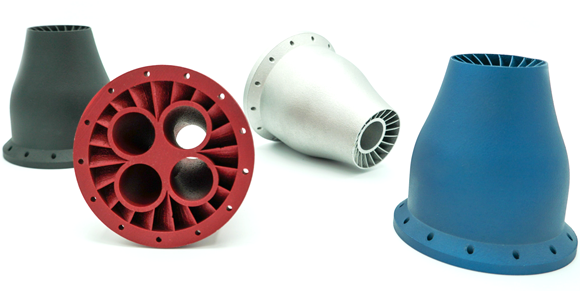

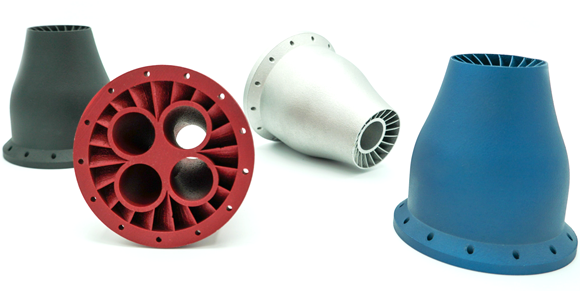

Said to require only a single-step heat treatment, without the need for Hot Isostatic Pressing (HIP), EOS Aluminium Al5X1 can also undergo electropolishing and anodising (Type II and Type III) to enhance both cosmetic (coloured) and corrosion-resistant properties. The potential colour choices for these applications are limitless, which can be particularly important for consumer-facing products.

EOS reports that the EOS Aluminium Al5X1 has been tested by multiple organisations, including world-leading semiconductor, aerospace, and defence companies. Early adopters have noted that the material’s exceptional performance, combined with its competitive cost-per-part (CPP), makes a strong business case for implementing it in production.

Brian Neff, founder & CEO of Sintavia, LLC, stated, “Since early 2023, we have been working to develop Al5X1 performance data and material allowables on behalf of our prime customers. Preliminary results are very promising, and we look forward to introducing Al5X1 across our thermodynamic product lines. Developing a higher performing aluminium alloy is of critical importance not only to us, but also to the industry as a whole.”

Dr Ankit Saharan, senior manager of metals technology at EOS, added, “A combination of high strength and high elongation for an aluminium alloy is critical for manufacturers in industries like aerospace, but equally crucial is delivering the property combination at a reasonable cost. Also interesting is that since the material can be anodized, this makes it very attractive to OEMs in areas like consumer electronics who are seeking to produce different coloured products to suite customers preferences, with the added bonus of corrosion resistance.”

EOS Aluminium Al5X1 will be commercially available for the EOS M 290 in November 2023, followed by commercial availability for the EOS M 400-4 in 2024.

Download Metal AM magazine