Elementum 3D releases IN625-RAM2 enhanced nickel superalloy build parameters

April 11, 2023

Elementum 3D, Erie, Colorado, USA, has announced the pilot release of a new high-speed Additive Manufacturing parameter set for its IN625-RAM2 enhanced nickel superalloy. The company has optimised the build speed of IN625-RAM2 and mechanical properties, through the development of 80 µm and 100 µm layer parameters, to boost production capacity and reduce the build cost of components additively manufactured with the material.

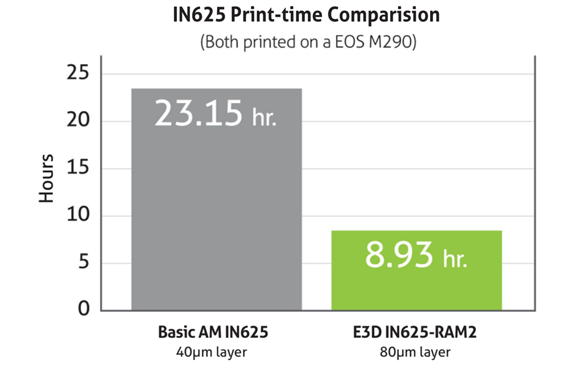

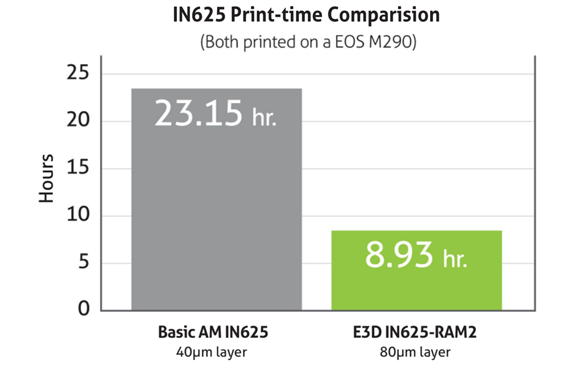

Using Elementum 3D’s IN625-RAM2 80 µm layer process parameters are said to enable Additive Manufacturing real parts in less than half the time of EOS’s 40 µm performance 1.10 parameters. While the exact time savings depend on the complexity and volume of the parts being manufactured, a case study with a full plate of high complexity parts resulted in 57% faster printing, while a build comprised of twenty simple test specimens delivered 61% faster build.

IN625-RAM2 is an enhanced Inconel 625 material developed by Elementum 3D that contains 98% commercial grade Inconel 625 and 2% Reactive Additive Manufacturing (RAM) additions. The RAM product phases increase nucleation during solidification and provide dispersion strengthening to IN625. This is said to result in a highly additively manufacturable alloy with good room and high temperature strength and corrosion resistance. These characteristics are ideal for IN625-RAM2 to be employed wherever Inconel 625 is used, including in the oil and gas, marine, and aerospace industries.

The RAM additions are reputed to also make the alloy a preferred choice for many applications that would otherwise require a higher strength alloy like Inconel 718, without needing a complex heat treatment.

Download Metal AM magazine