Dyndrite launches LPBF Pro Software and VIP Onboarding

November 9, 2023

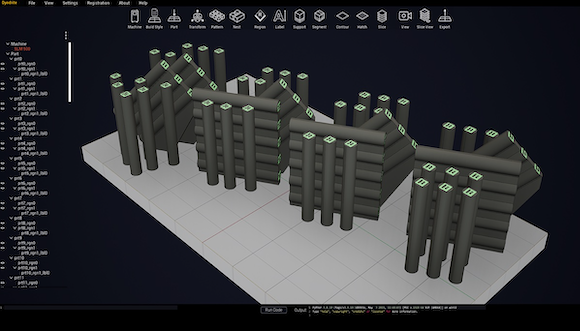

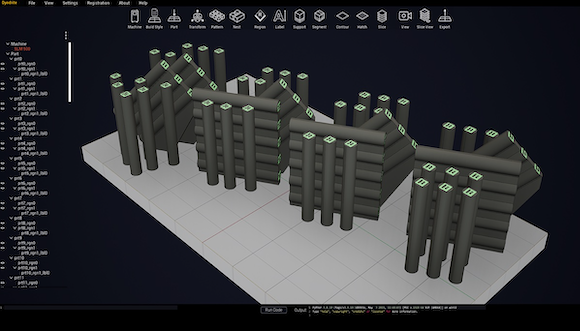

Dyndrite Corporation, a software developer based in Seattle, USA, has announced the immediate availability of VIP Onboarding for Dyndrite LPBF Pro, a new application for Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing professionals. This software is intended to empower AM users with previously unattainable build capabilities, accelerated build rates and cost savings.

Dyndrite LPBF Pro caters to users who are pushing past the boundaries of formats Dyndrite has called ‘outdated’ such as the STL and legacy applications that primarily rely on manual user interfaces and insider knowledge.

“In AM, software has become the bottleneck limiting industrial users from adopting and maximising the value from AM technologies,” explained Harshil Goel, CEO, Dyndrite. “Dyndrite’s mission is to break this bottleneck by equipping AM engineers with tools that make them effective at their job. These tools naturally deliver precision, traceability, and repeatability, serving not only those pushing the boundaries but also those seeking an on-ramp as new customers embracing AM as a scalable and reliable manufacturing process.”

Dyndrite LPBF Pro gives material, quality, process, and applications engineers scalable multi-threaded CPU and GPU-powered performance to solve tough geometry and computing challenges while streamlining build preparation processes. It enables materials experts to experiment, iterate and innovate, while quality engineers simplify and accelerate their qualification processes.

Through the now-available VIP Onboarding programme, customers receive direct hands-on support in applying Dyndrite to their metal Additive Manufacturing. Those interested can learn more here.

“For over six years, AMS has worked with aerospace, space and motorsport companies to push the boundaries of what’s possible in [PBF-LB],” said Rob Higham, CEO of Additive Manufacturing Services (AMS) Ltd. “Within two days of using Dyndrite we were able to print a thin-walled heat exchanger that, for over eighteen months others attempted and failed to print – such an achievement speaks for itself.”

Dr Jacob Nuechterlein, CEO, Elementum 3D, stated, “At Elementum 3D, our aim is to provide our customers with the highest quality product we can deliver. Using Dyndrite we surpassed our internal parameter set results on the very first try. Dyndrite LPBF Pro allowed us to increase the quality of our material parameters, while dramatically reducing the time it takes to prepare, test, and qualify each build. Dyndrite helps Elementum 3D deliver a better product to our customers.”

Kevin J Brigden, AMG Applications Engineering Manager, Renishaw, Inc, stated, “Renishaw has followed Dyndrite with interest since their launch. Upon receiving Dyndrite LPBF Pro with Quantum integration we immediately wanted to demonstrate how this connection could potentially increase the robustness of the certification of production processes. In particular, we want to show how volumetric segmentation can be used to deliberately induce non-conformance in specific regions of 3D geometry. The ability of the QuantAM API to allow complete control of RenAM500 series laser parameters enables a simulation of process degradation by deliberately ‘fudging’ the laser parameters in these regions of interest. This is merely the first step along that journey and in coming work, we will be leveraging machine learning approaches to help customers actually put this information to meaningful use.

“Using Dyndrite’s powerful geometry region segmentation we can easily create advanced complex toolpaths for the Renishaw machine than those normally generated with other software,” Brigden continued. “In a Design of Experiments we deliberately controlled and varied the laser power along the leading edge of an array of blade singlets, one of the most critical functional areas for performance and quality control. Exaggerated for visual effect here, the range of samples show increasing thermal input across blade samples to the point of deliberate non-conformance and poor build quality.

“This approach is novel as it shows how optimal print parameters can be systematically derived, and a functional process engineering window explored using Dyndrite software with the Renishaw QuantAM’s API to allow complete control of RenAM500 series laser parameters to make more performant parts faster, especially useful with multi-laser systems.

“These exciting results also offer the possibility to use simulation software to define the regions, again accelerating development and, during print, the ability to use machine learning to identify areas for subsequent further parameter refinement,” Brigden concluded.

Garett Purdon, Vice President of Sales – Americas at SLM Solutions, added, “We’ve enjoyed working directly with Dyndrite in support of SLM’s 3D metal printing product line, including our flagship NXG XII 600. We’ve seen first hand how Dyndrite’s capabilities help bring new customers to our platform and supercharge their Additive Manufacturing process. We look forward to working more closely with the Dyndrite team to further explore how their tools can enhance SLM’s value-proposition.”

Dyndrite LPBF Pro interfaces directly with a wide variety of metal AM machines including: Aconity3D, Renishaw, SLM, and others. Dyndrite is a member of the EOS developer network.

Dyndrite is currently exhibiting at Formnext 2023 in Hall 11.1, F41.

Download Metal AM magazine