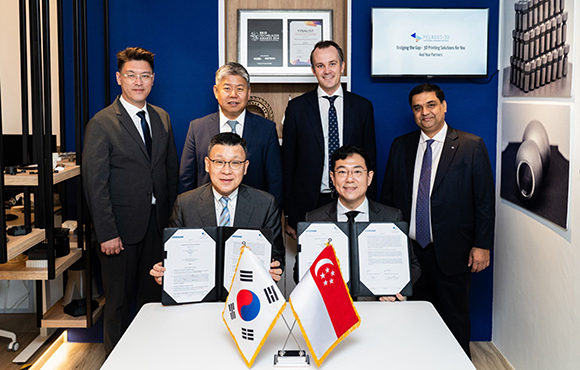

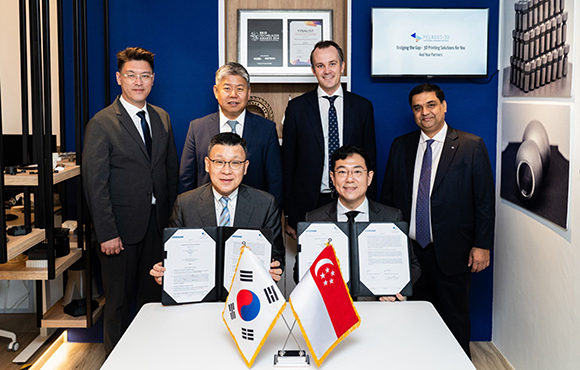

Doosan signs MOU with Pelagus 3D for maritime and offshore metal Additive Manufacturing parts

March 6, 2024

Doosan Enerbility, Changwon, South Korea, has signed a Memorandum of Understanding with Pelagus 3D, headquartered in Singapore, focused on advancing Korea and Singapore’s shipbuilding, aviation and maritime sectors via Additive Manufacturing. The partnership will include on-demand digital platform work for maritime and offshore metal parts and the planning of joint marketing and business development opportunities.

Doosan Enerbility will be responsible for the design, manufacturing and quality management of maritime and offshore spare parts made using Additive Manufacturing, while Pelagus 3D will be in charge of the online platform operation and identification of parts to be considered for the Additive Manufacturing, as well as the design and certification work.

“Doosan Enerbility has demonstrated to its customers across a wide range of industries, including the defence and aerospace sectors, the excellence of its AM technology and the economic feasibility,” stated Yongjin Song, Doosan Enerbility’s CSO. “Under this partnership, we plan to do our utmost to further expand the AM business and develop new markets.”

According to a study released by the global maritime research consultancy Drewry, it is forecast that the domestic market for maritime and offshore spart parts will grow from approximately KRW 300 billion ($225.7 million) in 2024 to KRW 600 billion ($451.4 million) by 2028.

Download Metal AM magazine