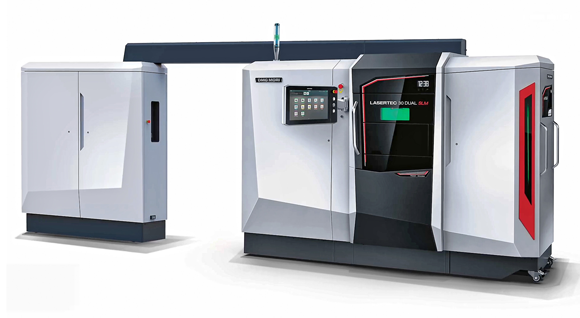

DMG Mori launches new Lasertec 30 Dual SLM Additive Manufacturing machine

March 19, 2020

DMG Mori has launched its new Laser Powder Bed Fusion (L-PBF) Additive Manufacturing machine. The Lasertec 30 Dual SLM machine is equipped with a pair of 600 W (optionally 1 kW) lasers, and can build either one component or several workpieces in parallel, providing flexibility for users to meet different order requirements and quantities.

The scan field of each laser is reported to cover the entire chamber area, enabling build rates of up to 90 cm³/h and raising output by as much as 80% compared with single-laser machines. Active cooling of the build area allows users to remove finished components quicker and thus prepare orders faster, leading to a further increase in productivity.

DMG Mori’s Optomet machine software is said to automatically recognise which scan strategy is most efficient for each job, ensuring that the machine always operates optimally. The adjustable focus diameter of the laser spot, from 300 µm down to 50 µm, enables high-accuracy melting, while a permanent filter with a lifetime of more than 3,000 hours offers a high level of operational safety.

The company stated, in the new machine’s design, it has retained the ergonomic design principles of the Lasertec SLM series, said to provide good accessibility for maintenance and to the build chamber. The intelligent, material-specific rePLUG unit for powder supply has a closed circuit under inert gas, allowing the powder to be exchanged easily and without contamination within two hours.

The Optomet software also includes functions for optimising power and exposure strategies for enhanced machine performance, as well as for controlling the temperature throughout the 300 mm cube build volume to normalise conditions and reduce residual stresses in the components being produced.

In addition to the new machine launch, DMG Mori has extended its DMG Mori Qualified Products (DMQP) programme to include peripheral components and accessories from third-party companies. The main focus of the programme is on economy through an unrestricted selection of powders and their return for recycling through selected DMQP partners, such as the global Heraeus group.

Through the DMQP programme, materials are available within a few working days when ordered from the DMG Mori online shop. These range from tool steels and stainless steel through aluminium and cobalt-chrome to Inconel and titanium.