Desktop Metal qualifies 316L stainless steel for high volume manufacturing with its Production System

April 21, 2021

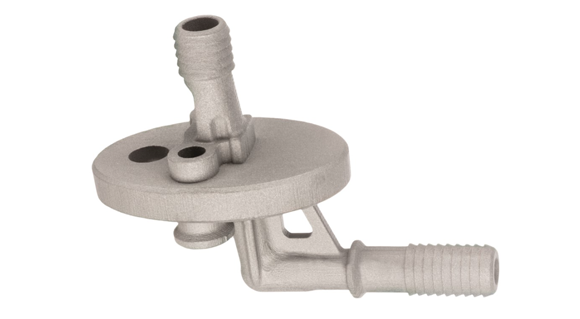

Desktop Metal, Inc, Burlington, Massachusetts, USA, has qualified the use of 316L stainless steel for its Production System™ platform. Known for its corrosion resistance and excellent mechanical properties at extreme temperatures, 316L stainless steel is well suited to applications in the most demanding conditions, such as parts exposed to marine or pharmaceutical processing environments, food preparation equipment, medical devices and surgical tooling.

Desktop Metal’s Production System machines use the company’s patent-pending Single Pass Jetting™ (SPJ) process. Based on Binder Jetting (BJT) technology, this allows users to additively manufacture components at speeds greater than that of laser-based AM systems.

“The qualification of 316L stainless steel with leading mechanical properties on the Production System platform is part of our aggressive roadmap to support an array of materials for Binder Jetting and a testament to the advantages of SPJ technology, which enables mass production throughput without sacrificing part performance and repeatability,” stated Jonah Myerberg, co-founder and CTO of Desktop Metal.

“With 316L on the Production System P-50, businesses will now be able to leverage Additive Manufacturing to produce complex, end-use parts suitable for use in harsh environments at volumes and costs competitive with conventional manufacturing.”

Through extensive testing, Desktop Metal’s materials science team has validated that 316L stainless steel additively manufactured on Production System technology, and sintered by Desktop Metal, meets MPIF 35 standards for structural Powder Metallurgy parts set by the Metal Powder Industries Federation (MPIF).

“As innovators in the automotive, medical, consumer products and petrochemical industries continue to embrace the benefits of Additive Manufacturing, implementing applications made possible with 316L stainless steel, we will begin to see even more widespread adoption of binder jetting technology,” added Myerberg. “Materials that push the boundaries of what AM technology can do will continue to advance the industry and drive unparalleled throughput while significantly reducing cost and waste.”