Desktop Metal launches Desktop Health for patient-specific Additive Manufacturing applications

March 15, 2021

Desktop Metal, Inc, Burlington, Massachusetts, USA, has launched Desktop HealthTM, a new business line focused on accelerating the growth of Additive Manufacturing solutions for dental, orthodontic and otolaryngology applications, based in Newport Beach, California, USA.

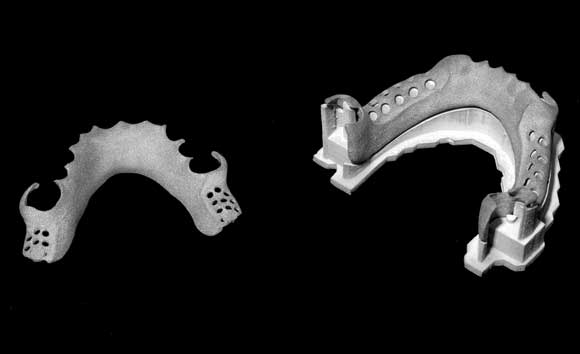

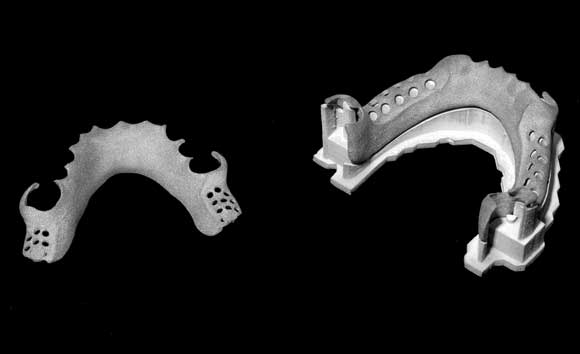

Desktop Metal states that the combination of new AM technologies, including bioprinting, high-speed metal Binder Jetting, and the use of advanced biocompatible materials across polymers, ceramics and metals, puts Desktop Health in a strong position to develop advanced healthcare applications.

“Today the world manufactures more than $85 billion in medical and dental implants each year,” commented Ric Fulop, CEO and co-founder of Desktop Metal. “We think a large percentage of these parts could be printed and made patient-specific before the end of the decade, making this market a key opportunity for Desktop Metal. We look forward to building a best-in-class team to work with our industry partners to bring patient-specific solutions to the market at scale.”

To lead the new business initiative, Desktop Metal has appointed healthcare executive Michael Mazen Jafar as president and CEO of Desktop Health. Jafar brings nearly twenty years of experience creating and scaling breakthrough healthcare products.

Jafar most recently served as Chief Commercial Officer of Evolus, a performance beauty company, where he oversaw the launch of its flagship product, Jeuveau®. For sixteen years, Jafar also led the ophthalmology and medical aesthetics division for Allergan, culminating as VP Marketing, U.S. Medical Aesthetics, and working on several of the company’s marquee brands, including Botox® Cosmetic, JUVEDERM® Collection and CoolSculpting®.

“I am excited to join Desktop Metal at such an important time in medical technology,” Jafar stated. “I want to build on years of the company’s research and development to bring its core technology and advanced materials to many healthcare specialities. Desktop Health has a mission to change the way patients experience personalized healthcare, through innovation and science-based solutions.”

Backed by twenty years of research, more than 1,400 published papers and 3D Bioplotter & Digital Light Processing (DLP) technology, coupled with high-speed metal Binder Jetting Additive Manufacturing solutions, Desktop Health plans to leverage proven technology to create patient-specific solutions in the medical field.

“It’s a true privilege to work with leading technology alongside physicians, surgeons and dentists to advance personal care,” added Jafar. “Our technology is widely used for customised in-office digital dentistry, makes customised metal implants possible, and has enabled exploration of applications such as bone regeneration, cartilage regeneration, and soft tissue biofabrication. We look forward to building on our success and ingenuity as we research extensions of our core technology across cardiology, orthopaedics, ophthalmology, dermatology and plastic surgery.”