Desktop Metal announces two new metal AM systems for prototyping and mass production

April 28, 2017

Desktop Metal’s Production System is designed for the mass Additive Manufacturing of metal parts (Courtesy Desktop Metal)

Advanced manufacturing company Desktop Metal, based in Burlington, Massachusetts, USA, has launched two new metal Additive Manufacturing systems covering the full product lifecycle from prototyping to mass production. According to the company, the new systems – DM Studio and DM Production – mark a ‘fundamental shift’ in how products will be developed and brought to market, reducing production costs and increasing speed, safety and net quality.

The DM Studio System has been designed as the first ‘office-friendly’ metal AM system for rapid prototyping and claims to be ten times less expensive than existing technologies. The system is sold as a complete platform, including a printer and microwave-enhanced sintering furnace with the ability to deliver complex geometric shapes.

Desktop Metal’s new Studio System is designed for office-based prototyping (Courtesy Desktop Metal)

Desktop Metal have stated that DM Studio will help to eliminate the need to house Additive Manufacturing systems in large industrial facilities through the use of Bound Metal Deposition, a proprietary process which uses no hazardous technologies and is similar in method to Fused Deposition Modelling, used in plastic AM. In addition, by using cloud-based software to link stages of the workflow, the system is expected to help eliminate the need for dedicated operators, making it possible to input designs direct from CAD software.

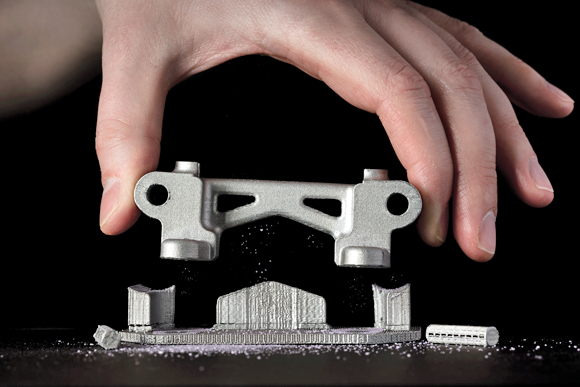

The DM Studio will also feature Desktop Metal’s proprietary Separate Supports, a type of support structure which can be removed safely by hand, along with swappable print cartridges for rapid material changes. It is reportedly compatible with a large variety of metal alloys, making it possible to prototype parts in the material that will be used in mass production.

The DM Production System is designed for the mass Additive Manufacturing of metal parts. According to Desktop Metal, this will be the fastest AM system available for mass production of high-resolution metal parts. Using the company’s proprietary Single Pass Jetting technology, the DM Production system claims to operate at speeds one hundred times faster than most laser-based Additive Manufacturing systems, having the potential to dramatically reduce cost-per-part and allow metal AM to compete with mass production techniques such as casting.

The DM Studio will feature Desktop Metal’s proprietary Separate Supports, a type of support structure which can be removed safely by hand (Courtesy Desktop Metal)

“Until now, metal 3D printing has failed to meet today’s manufacturing needs due to high costs, slow processes and hazardous materials,” stated Ric Fulop, CEO and Co-founder of Desktop Metal. “With a team of some of the world’s leading experts in materials science, engineering and innovation, Desktop Metal has eliminated these barriers by developing metal 3D printing systems that can safely produce complex, strong metal parts at scale.”

Since its inception in October 2015, Desktop Metal has reportedly raised $97 million and attracted major investors, including GV (formerly Google Ventures), BMW Group, GE, Lowe’s, NEA, Kleiner Perkins Caufield & Byers, Lux Capital, Saudi Aramco and Stratasys. To date, the company has filed 138 patents. The founding team includes Jonah Myerberg, Chief Technology Officer; Ely Sachs, MIT professor and early innovator in Additive Manufacturing; Yet-Ming Chiang, MIT professor in materials science; Christopher Schuh, Chairman of MIT’s Department of Materials Science & Engineering; metallurgist A. John Hart, MIT professor in manufacturing and machine design; and Rick Chin, VP of Software, formerly of SolidWorks and Xpress 3D.

Desktop Metal’s Studio System features swappable print cartridges for rapid material changes (Courtesy Desktop Metal)

“The rapid pace of innovation in technology is enabling OEMs to design, produce and deliver their products differently. I see a huge potential for the highly competitive automotive industry to accelerate product development and production,” commented Uwe Higgen, Managing Partner of BMW i Ventures. “Desktop Metal’s technology offers a new way for the manufacturing industry to be smarter, faster and more cost effective with metal 3D printing. Whether it’s rapid prototyping or output at scale, a solution for printing metal parts that is competitive to the traditional manufacturing processes is certain to change the face of automotive design and production.”

“Caterpillar’s Parts Network has twenty-one distribution centres around the world that hold hundreds of thousands of service parts to provide over 2,000 dealer locations with the parts needed to provide our customers with their expected uptime,” added Don Jones, Caterpillar Global Parts Strategy Manager. “By leveraging a portion of 3D printing for metal parts, we will be able to enhance best in class service with lower inventory investment. We are excited to evaluate the Desktop Metal suite of products, which will allow us to print metal parts at high speed and minimal post processing and environmental constraints closer to our customers, reducing the need to expedite and ship critical parts from across the globe.”

The DM Studio System will be available to reserve from May, with shipments beginning in September 2017, while the DM Production System is available on reserve from May for shipping in 2018.