Designer’s new titanium golf club additively manufactured by Farsoon FS200M

January 29, 2024

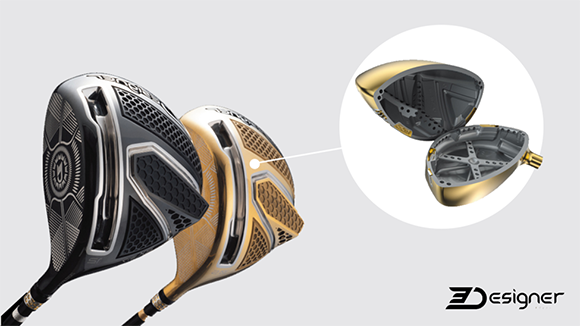

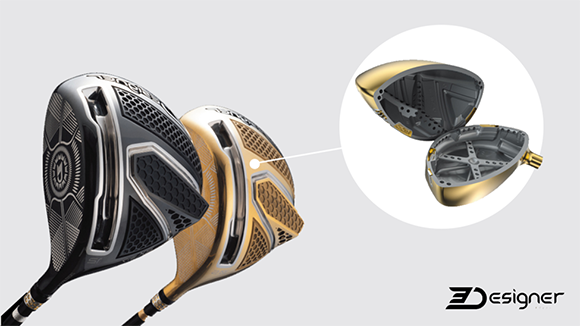

Designer, a Japanese golf brand from KL Planning, has launched an additively manufactured titanium golf club with a lightweight and high-strength design said to offer the golfer increased distance, accuracy, stability and greater forgiveness. Launched at the recent PGA Show in Orlando, Florida, the titanium club head is manufactured using a dual-laser FS200M AM machine from Farsoon Technologies, based in Changsha, China.

Built using a customised titanium alloy, the Designer club head features a high-speed impact surface with enhanced ductility and strength, said to provide the perfect strike.

Compared to a cast or forged design, metal Additive Manufacturing allows for faster design and verification iterations, as well as enabling innovative designs that were previously impossible, such as self-supported internal structures contributing to thinner, stronger, and textured external surfaces. Farsoon’s metal AM technology also makes it possible to produce the golf club head in a single piece, resulting in improved precision and performance compared to traditional manufacturing processes. The integrated structure offers greater resistance to twisting, increased stability, and driving distance for the player.

The Designer AM club heads incorporate multiple aerodynamic features that allow air to flow faster and smoother over the club’s integrated geometries. This reduces drag, resulting in improved head stability and speed. Additionally, the club heads are equipped with a distinctive ‘Sound Window’ design, intended to provide a more pleasing sound upon impact.

Using Additive Manufacturing is said to reduce cost per part by about 70% from design to manufacturing compared to the conventional process. A customised multi-layer thickness parameter has also been developed for higher productivity.

Download Metal AM magazine