Dedicated website highlights TWI’s Additive Manufacturing consultancy, research and training

November 10, 2016

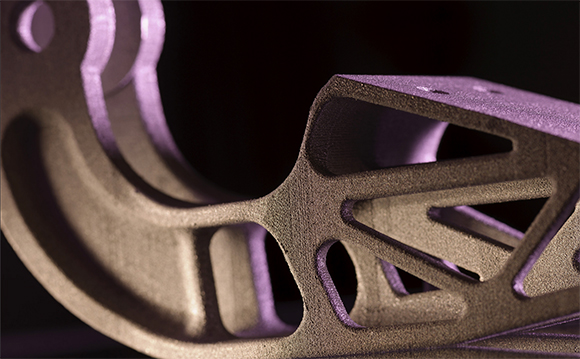

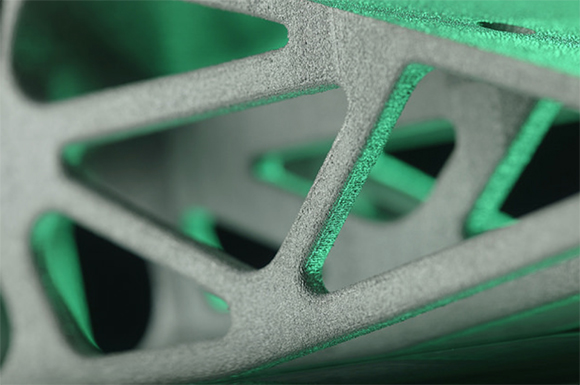

Selective Laser Melting (image courtesy by TWI Ltd)

TWI Ltd, Cambridge, UK, one of the world’s leading independent research and technology organisations, has been working in metal Additive Manufacturing (AM) technology development for the last 25 years. During this time it has gained a detailed understanding of every aspect of its use, from design, process selection and commercial implementation to testing, validation and certification.

To better showcase the full extent of services the company provides in this area, TWI has launched a dedicated AM website. The new site provides an overview of AM technology and offers a number of interesting case studies discussing various research and development projects undertaken.

TWI claims to have worked with a diverse range of organisations and industry sectors including aerospace, oil and gas, defence, power and medical, identifying ways for them to exploit the opportunities AM presents and helping them integrate AM into their products. It is also supporting standards organisations and global companies to expedite the industrial exploitation and adoption of AM technologies and to help businesses fully realise the benefits offered by AM.

The AM team is supported by the rest of TWI’s engineering capability, with hundreds of scientists, engineers and researchers specialising in every facet of materials joining, structural integrity and materials science.

www.twiadditivemanufacturing.com

Selective laser melting is an AM process that uses a laser to selectively melt and fuse sections of a layer of powder onto a substrate. After each layer is fused, the substrate is retracted vertically, another even layer of powder is spread across the top, and the process repeats.

The path of the laser is determined by a CAD model that is sliced into layers less than 100µm thick using specialist software. Selective laser melting takes place in a vacuum chamber filled with inert gas, to prevent oxidisation of the powder. Unused powder can be recycled and used for the next build. (image cortesy by TWI Ltd.)