Daido Steel releases new die steel-based powder for Additive Manufacturing

November 17, 2022

Daido Steel Co., Ltd., headquartered in Nagoya, Japan, has announced the availability of DAPTM-AM LTX die steel-based metal powder for Additive Manufacturing, the second product in its DAPTM-AM (Daido Alloy Powder – for Additive Manufacturing) series of metal AM powders. The gas atomised powder offers low oxygen content and high flowability, and is particularly suitable for large sized products.

Developed specifically for Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing, DAPTM-AM LTX is based on SKD61 (JIS steel), which is widely used for dies and moulds. The new alloy enables the production of components which have been historically difficult with conventional die steel-based powders. Unlike maraging steel powders, DAPTM-AM LTX does not contain cobalt, and tests show that once additively manufactured, the material has the same performance as moulds made from traditional SKD61 steel.

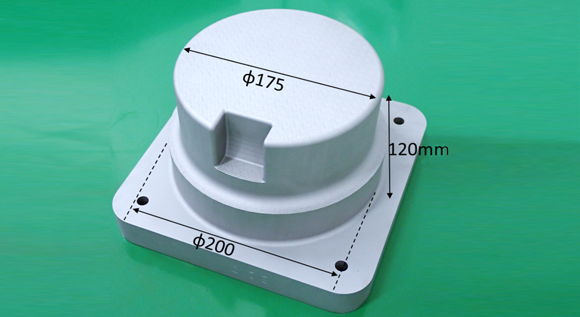

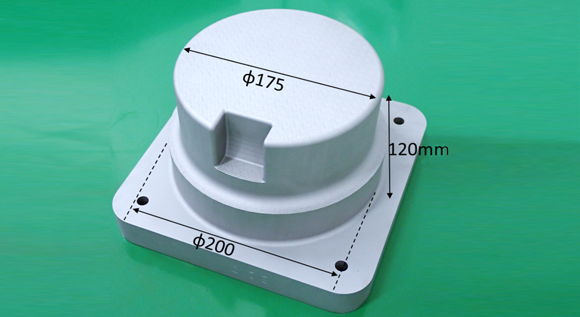

In April 2021, Daido launched DAPTM-AM HTC, a high thermal conductivity metal powder and the first product in the DAPTM-AM range. DAPTM-AM HTC is a cobalt-free die steel-based powder that suppresses cracking and enables high-performance moulds to be additively manufactured. However, DAPTTM-AM HTC is only suitable for additively manufacturing moulds up to 150 mm square, any larger than this is more suited to DAPTM-AM LTX, being ideal for parts exceeding 150 x 150 mm.