Cubichain Technologies brings blockchain cyber-security to the Additive Manufacturing Industry

November 18, 2016

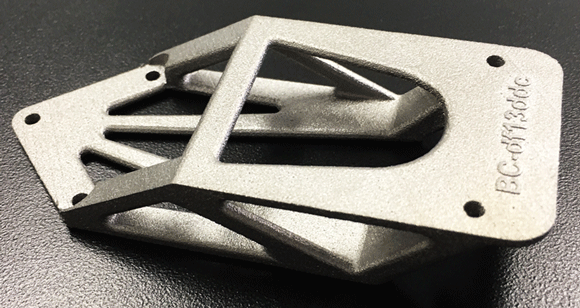

A topology optimised additively manufactured Ti-6-4 aerospace part employing part build data transmitted and verified using a Cubichain network and embedded hash encrypted serial number. CalRAM integrated the blockchain hash serial number during the printing cycle

Cubichain Technologies, a Californian start-up focused on developing and deploying cyber-securing and anti-counterfeiting tools, along with CalRAM LLC., experts in the production of metal powder bed fusion components for aerospace and space applications, have announced the successful deployment of a blockchain network to protect the digital data stream for additively manufactured aerospace titanium parts.

Using the MultiChain private blockchain platform, based on Bitcoin Core, Cubichain Technologies stated that it is developing an application that interfaces with Additive Manufacturing industry processes to encrypt critical digital data associated with the binary part definition. It then stores that information on an internationally distributed private blockchain.

The information stored on the blockchain provides an immutable copy of the original encrypted data that is used to verify that transmitted copies of the digital part data have not been altered, tampered with or otherwise hacked. The demonstration provided proof that the Cubichain technology can easily identify part files which have been tampered with by recognising the difference in a single data bit in the binary part file.

“Both Additive Manufacturing and blockchain networks are disruptive technologies; combining the two will undoubtedly revolutionise the future of manufacturing. We see the greatest threats to Additive Manufacturing as cyber-physical hacking and counterfeiting; the deployment of a blockchain can combat both. It’s very exciting technology,” stated Shane Collins, Director Additive Manufacturing Programs for CalRAM.

It is anticipated that addressing the $1.7 trillion/year product counterfeiting market will lead the way for cross-industry adoption of the Cubichain solution and the novel blockchain approach. The ultimate deployment for the blockchain is when there is an immutable identification embedded in the part that cannot be altered and it is preserved in an equally immutable ledger.

This capability is said to be within reach of the Additive Manufacturing industry through the use of layer-wise build inscription of identification in the part during the build process as shown in the image of the aerospace titanium part built by CalRAM employing the Cubichain data management. Through the integration of these leading edge technologies in a standardised process, counterfeiting high value, mission critical parts will become exceedingly difficult and no longer profitable.

“In the next few years, strategic deployment of additive manufactured parts is anticipated to increase exponentially while the ability to protect the digital stream will outstrip existing centralised cyber-security measures giving way to the scalability and unbreakable security of the blockchain. Like Everledger for the Diamond industry, Cubichain wants to define an industry standard for manufacturing data security and elimination of counterfeit parts worldwide. What we accomplished today provides the proof-of-concept for a much larger closed-loop solution currently being developed,” added Dr Kenneth Newell, co-founder of Cubichain Technologies.

www.cubichain.com