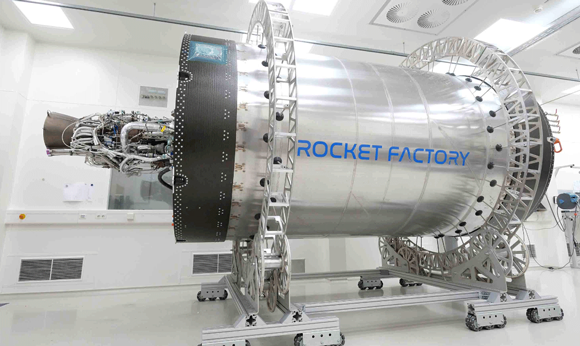

Conflux Technology partners with Rocket Factory Augsburg to develop aerospace heat exchangers

April 6, 2023

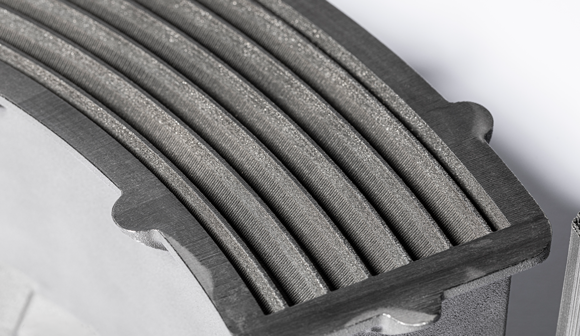

Conflux Technology, an Australian company using metal Additive Manufacturing to produce heat exchangers, and German-based Rocket Factory Augsburg (RFA), are entering into a partnership to embed a Conflux heat exchanger into a gas duct of an orbital rocket. The project is part of the Australian Space Agency’s Moon to Mars Initiative: Supply Chain Capability Improvement Grant Program.

Under the project, a $1 million AUD grant is being used to develop and manufacture the additively manufactured heat exchanger.

“Conflux is partnering with RFA to embed next generation heat exchange technology into a rocket engine. At Conflux we are establishing ourselves as leaders in the development and commercialisation of 3D printed thermal solutions and relevant materials for extreme applications. With support from the Australian Space Agency’s Moon to Mars Grant Supply Chain Capability Improvement grant, we are now applying it to the rapidly expanding space industry,” stated Dan Woodford, Chief Commercial Officer, Conflux Technology.

The Supply Chain Capability Improvement Grant Program is part of the Australian Space Agency’s Moon to Mars Initiative. The initiative supports Australian organisations with projects that could contribute to NASA’s inspirational endeavor to go to the Moon and on to Mars. This initiative is also an important element of the Agency’s goal to transform and grow the Australian space industry. Conflux is proud to be one of the innovative Australian businesses to be awarded funding under this initiative.

Download Metal AM magazine