Concept Laser announces new metal AM machines, software, peripherals and materials

November 15, 2016

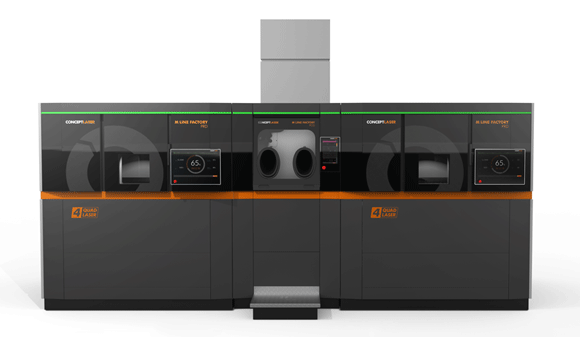

The M LINE FACTORY architecture from Concept Laser allows separation of the machine units used for part production (M LINE FACTORY PRD) and the set-up and dismantling processes (M LINE FACTORY PCG) (Courtesy of Concept Laser GmbH)

Concept Laser, based in Lichtenfels, Germany, has announced the commercial launch of its M LINE FACTORY, offering what is claimed to be a completely new approach in machine architecture with an unprecedented level of automation and innovation. During formnext 2016, Frankfurt, Germany, November 15-18, the company also introduced its Mlab cusing 200R in the small machine segment and its X LINE PCG in the large machine segment as an option for the convenient and secure removal of the powder following the production process.

As well as the availability of new precious metal alloys, a new product was also unveiled in the area of the QM modules. The new laser power meter, QM Cusing Power, now enables the laser power to be measured directly on the build area

The new M LINE FACTORY is intended to boost metal AM production.

For the first time, part production as well as set-up and dismantling processes will take place in two independent machine units, so that they can be operated separately from one another. This now enables production processes to run in parallel rather than sequentially so that downtimes are considerably reduced and the availability and output quantity of the process chain is thus increased.

The M LINE FACTORY PRD, as the production unit, has a max. build envelope of 400 x 400 x 425 mm³ (x,y,z) and is optionally equipped with 1 to 4 laser sources, each delivering 400 W or 1,000 W of laser power. The core of the unit is three independent modules, the dose module, the build module and the overflow module, which can be individually activated for the first time and therefore do not form one continuous unit. The individual modules are moved via a tunnel system inside the machine. This means that, for example when new powder is supplied, the empty powder storage module can automatically be replaced by a new module immediately without the build process necessarily needing to be interrupted, as was previously the case.

The production unit and processing unit can be combined in any way you want. Here is an example of a processing unit with two production units (Courtesy of Concept Laser GmbH)

Finished build jobs can now also be moved out of the machine with the dedicated module and replaced directly by a new prepared build module so that production operations can be resumed immediately. Furthermore, a new two-axis coating process has been implemented and this permits the return run of the coater to be performed alongside the exposure without the spatter problems that usually arise in the market today with systems that coat in both directions. This results in a substantial saving on time during the coating process in combination with a pursuit for the highest quality. Also under preparation is the integration of an automated tool changing system, as is the case with CNC machine technology, which promises flexibility as well as time advantages when setting up the machine, and further reduces the level of manual intervention by the operator.

The physically separate, autonomous M LINE FACTORY PCG is available as the processing unit for set-up and disarming processes. This enables optimum use windows right through to the ideal of 24/7 availability of the machine technology. The new processing unit has an integrated sieving station and powder management. There is now no need for containers to be used for transportation between the machine and sieving station. Unpacking, preparations for the next build job and sieving therefore take place in a self-contained system without the operator coming into contact with the powder. An automated material flow is another unique selling point. This allows self-contained modules for transport and material provision to be used.

The associated software suite CL WRX 3.0 includes various user roles with different authorisation levels which enables operator-specific, transparent control and monitoring of all process operations. In addition, it is an open structure with interfaces to CLS, ERP, machine technology and automation technology. The intention is that the system should also be able to integrate remote diagnosis, service monitoring and later also diagnostic devices. Another advantage is the connectivity with different output media such as panels, PCs, laptops, or smartphones that an employee can use to stay on top of things.

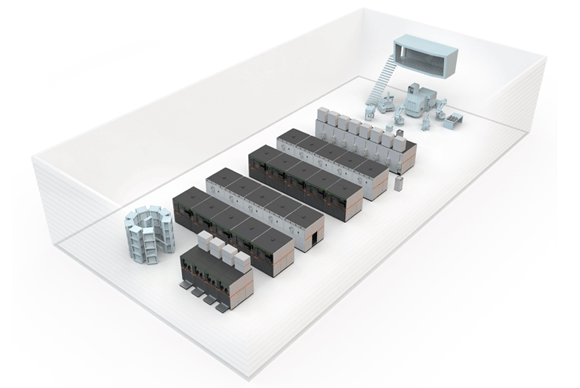

The ‘smart factory’ is a flexibly expandable, high-grade automated and centrally controllable meta production system which is focused fully on the production assignments in hand and thus enables the economical series production of additive metal components (Courtesy of Concept Laser GmbH)

The modular machine technology of the M LINE FACTORY forms the core of Concept Laser’s ‘AM Factory of Tomorrow’ concept which also makes provision for upstream and downstream stages of the production process as well as links to conventional manufacturing methods. The concept consistently implements the basic idea of Industry 4.0 in the form of automation, interlinking, and digitization, and thus permits the economical series production of additive metal components.

Machinery and plant technology: Premiere of the new Mlab cusing 200R

The Mlab cusing 200R offers larger build plate, bigger build volume and more laser power (Courtesy of Concept Laser GmbH)

In addition to the long-standing Mlab cusing R, Concept Laser has now unveiled its big brother, the Mlab cusing 200R. This makes it possible to manufacture even larger parts with much greater productivity, without the machine losing any of its familiar compactness. Highlights of this new development include the doubling of the laser power to 200 watts, an expanded build area covering 100 x 100 mm2(x,y) and 54% more build volume overall thanks to a z-axis of an equally enlarged 100 mm making it possible to manufacture even larger parts.

For the Mlab cusing 200R, Concept Laser offers an inertised sieving station as a stand-alone unit (QM Powder S). QM Powder S enables independent and automated sieving alongside the production process. The user can apply a variable number of sieves (1 – 3 units). A three-dimensional sieving motion enables optimum utilisation of the open sieve surface area.

Safety was said to be right at the top of the development list for the Mlab cusing 200R. The new model has water-floodable filter modules and involves physical separation of the process and handling chambers, which is typical for Concept Laser and ensures maximum safety and easy handling. The concept of the closed system was a must-have for the Mlab 200R and all process steps take place under inert gas, shielded from external influences.

QM modules: Presentation of the laser power meter QM Cusing Power

The company also unveiled its latest tool in the area of quality assurance and monitoring, QM Cusing Power. This tool now enables the laser power to be measured directly on the build area. The core of this new concept is a compact measuring device with a digital display. This measuring device can be used with all machines from Concept Laser (from machine software version 2.0.3.5). The measurement takes place under inert gas and no additional cooling is required.

Peripherals: Presentation of the X LINE PCG unpacking station

With the X LINE 2000R, Concept Laser not only offers the machine with the world’s largest build envelope, but also provides the unpacking station to go with it in the form of the X LINE PCG. This is recommended as an optional addition to the previous model, the X Line 1000R. It makes it possible to easily clean components within an inert chamber. It is used for removing powder even in highly complex cavities and open support structures and for returning it to the powder circuit. The X LINE PCG makes it possible to clean components within the inertised process chamber. The programmed pivoting about two axes allows the component to be rotated on the platform and reliably removes the excess powder with a rotary movement. This aspect of automation allows the manufacturing process to proceed faster and more effectively.

New precious metal alloys for use on Mlab cusing and Mlab cusing R

Concept Laser added new precious metal alloys to its range of materials for use on Mlab cusing and Mlab cusing R. These included silver alloy (930 ‰), yellow gold (18 carat, 3N), rose gold (18 carat, 4N), red gold (18 carat, 5N) and platinum alloy (950 ‰). The processing parameters are provided by Concept Laser however the materials themselves are to be procured from the relevant powder manufacturer.