Chiron to showcase AM Cube and new analysis processes at Formnext 2021

October 8, 2021

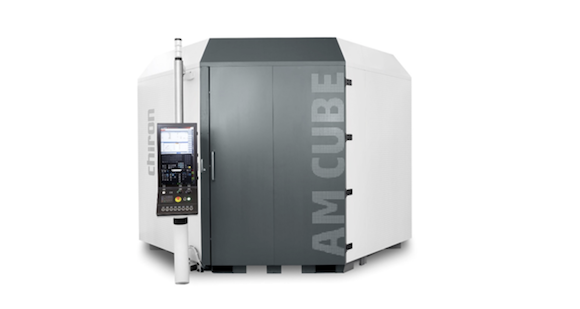

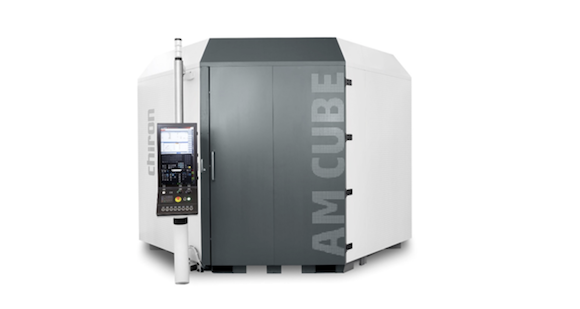

The Chiron Group, Tuttlingen, Germany, is scheduled to demonstrate its metal Additive Manufacturing machine the AM Cube for the first time in person at Formnext 2021 in Frankfurt, Germany, this November. Since the machine’s introduction at Open House Online, it’s reported to have proven itself in industrial applications and now offers a range of additional options.

The event will also offer potential users the chance to see two new features in the interactive showroom: the comprehensive documentation of process data with DataLine AM and the ability to record the welding process in real-time with VisioLine AM.

The AM Cube is said to be well suited to a variety of different processes and industries, including mechanical engineering, tool manufacturing, energy production and aerospace. The machine is capable of additively manufacturing parts using both wire and powder Directed Energy Deposition (DED), with three deposition heads that can be changed fully automatically during the process.

In order to analyse and optimise its AM processes in a targeted way, Chiron created two new digital systems for the machine: DataLine AM displays, records and documents all relevant process data in real-time, while VisioLine AM creates and saves video files recorded by multiple camera systems (e.g. the melt pool camera, thermal camera, workpiece camera, working area camera).

At Formnext, Chiron’s AM teamt will demonstrate the interaction of AM and machining in a use case, and are also scheduled to present a preview of a second project: AM Coating. This is a system designed for applying particularly hard coatings on brake disks and rotationally symmetrical components.