Carnegie Mellon University introduce melt pool measurement method using commercial camera

July 21, 2023

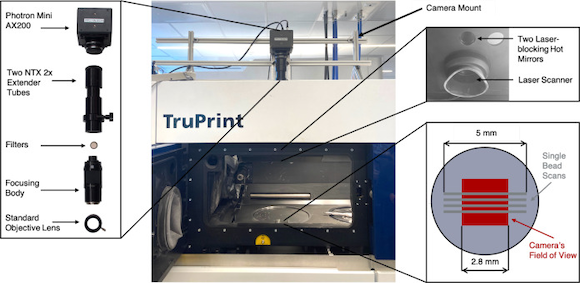

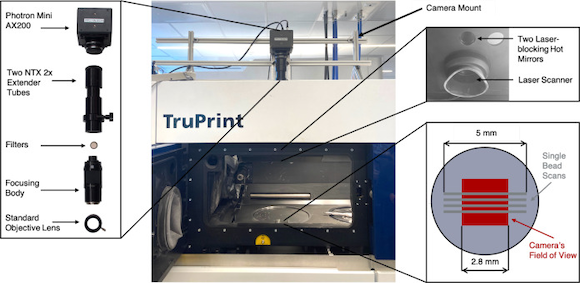

New research from Carnegie Mellon University, Pittsburgh, Pennsylvania, USA, and National Institute of Standards and Technology, Gaithersburg, Maryland, has been published in Additive Manufacturing introducing an experimental method to measure melt pool temperature using a single commercial colour camera. Accurate temperature measurements of the melt pool can be used to predict and identify defect signatures, such as keyholing, which can lead to cracking and porosity that can result in unsuitable parts.

Jack Beuth, a Professor of Mechanical Engineering at Carnegie Mellon stated, “These melt pool temperature field measurement techniques and the measurements themselves are entirely unique.”

“Our methodology can be applied to any colour camera to monitor and better understand melt pools that yield high-quality parts for a wide range of AM processes,” added Jon Malen, Professor of Mechanical Engineering.

Reportedly, the team used a commercial colour camera with a built-in Bayer filter on the sensor. Two green pixel filters were used for every red and blue pixel filter to sense visible colours. Each pixel sensed light from only one colour, enabling the team to acquire unique measurements for each pixel. The team reconstructed a full-colour image using a technique called ‘demosaicing’, and measured the ratio between each of its colours to calculate the temperature. This radiometric approach avoids complications related to surface properties and view factors, which challenge the application of conventional IR imaging to AM processes.

“Without analysis, the temperatures of these liquid metals are interesting but don’t directly explain the physics in the melt pool,” explained Alex Myers, a PhD candidate co-advised by Malen and Beuth. “We determined unknown parameters in a computational fluid dynamics model using the experimental results to tell us more about what happens at the microscale of the melt pool.”

Peak temperatures in the melt pool can reportedly help researchers to understand material vaporisation during production. Whereas the gradient toward the tail of the melt pool helps them to understand the microstructure of the final part. Understanding the physics in the melt pool is said to be critical to ensuring quality parts because if too much of the material vaporises or the melt pool becomes unstable, manufacturers could end up with entirely different material properties and defects that render the part unusable.

“We can look into the science of AM now and not just monitor the process,” said Guadalupe Quirarte, a PhD candidate in Malen’s lab.

Beuth added “This is opening the door to a more complete and fundamental understanding of how process parameters affect melt pool physics, which is a central issue in AM process development.”

Moving forward, researchers at Carnegie Mellon has reported its plans to use this technique to understand different processes such as Wire Arc Additive Manufacturing (WAAM) and Directed Energy Deposition (DED).

“These measurements and analogous simulations are opening the door to a more complete and fundamental understanding of how process parameters affect melt pool physics, which is a central issue in AM process development,” concluded Beuth.

‘High-resolution melt pool thermal imaging for metals additive manufacturing using the two-color method with a color camera’ is available to read here, in full.

Download Metal AM magazine