Canadian Research Council partners with PolyControls on Cold Spray Additive Manufacturing

July 23, 2019

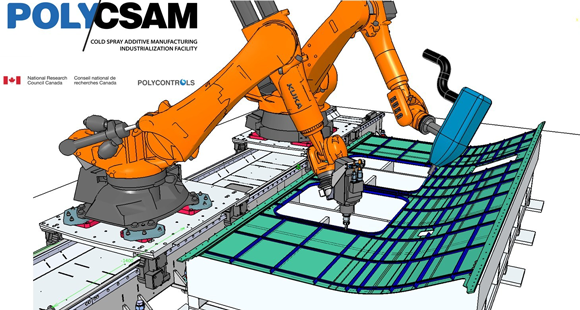

The National Research Council of Canada (CNRC), headquartered in Ottawa, is partnering with PolyControls, a surface engineering solutions and equipment integration specialist based in Quebec, Canada, on the opening of a new research facility which will give manufacturers and researchers the opportunity to study, adopt and deploy metal Cold Spray Additive Manufacturing (CSAM) technology.

Expected to open in February 2020, the Poly/CSAM facility will be located at the NRC’s Boucherville site in Quebec. Specifically, Poly/CSAM will focus on scaling-up the CSAM process by enabling the adaptation of laboratory-developed technology to meet factory and mass production requirements. The six year venture will also offer training for manufacturers to ensure the technology is implemented safely and securely.

“The National Research Council of Canada acknowledges the value and importance this collaboration can offer the industry and the Canadian advanced manufacturing ecosystem,” stated François Cordeau, Vice President of Transportation and Manufacturing, National Research Council of Canada.

“We see great potential in bringing together different stakeholders to enable innovation and to build a network of industrial partners for a stronger Canadian supply and value chain,” he continued. “Our renowned technological expertise and capabilities in Additive Manufacturing research and development will support Poly/CSAM and contribute to developing demonstration platforms targeted at end user-industries and cluster networks.”

The project is being supported by Investissement Québec, the Business Development Bank of Canada, and Bank of Montreal, with an initial investment estimated at CAD $4 million over the next six years. CNRC will also support technology development and provide strategic advice and technical services with a professional team of over forty experts.

Poly/CSAM is expected to offer a combination of unique technologies including surface preparation, coating and part manufacturing by CSAM; local, laser-based thermal treatment; in-situ robotic machining and surface finishing; new sensor technologies; extensive data logging and analytics; and machine learning.

Luc Pouliot, Vice-President Operations, Polycontrols, commented, “Polycontrols is eager to leverage its proven track record in thermal and cold spray implementation (aerospace and surface transportation industries) to showcase its capabilities as a large-scale manufacturing integrator offering custom equipment platforms with the objective of bringing disruptive technologies such as hybrid robotic manufacturing, data analytics and machine learning (supported by Artificial Intelligence) to the shop floor. We see Poly/CSAM as a way to strengthen Canada’s industrial leadership in Cold Spray Additive Manufacturing and becoming more agile and competitive on the national and international scene.”