Canadian AM centre focuses on manufacture of marine certified components

July 31, 2018

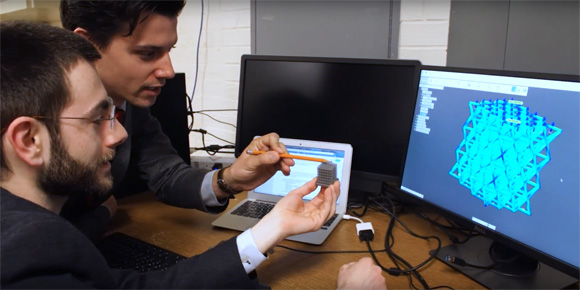

Researchers at Canada’s Marine Additive Manufacturing Center of Excellence (Courtesy University of New Brunswick)

The University of New Brunswick, Canada, has purchased a GE Additive Concept Laser M2 cusing metal Additive Manufacturing system for use by the Marine Additive Manufacturing Center of Excellence, along with its training partners New Brunswick Community College, the College Communautaire du Nouveau-Brunswick, and Nova Scotia Community College.

The centre, which is being spearheaded by The University of New Brunswick, is said to be the first in Canada to use metal Additive Manufacturing for the production of certified parts for the marine industry. Key research and development topics include enhanced corrosion protection, hybrid AM, smart parts and blast resistance,

This initiative is the result of a partnership with UNB, Custom Fabricators and Machinists (CFM), and community colleges in New Brunswick and Nova Scotia. As well as being the first in the country to produce certified AM marine parts, the centre is also said to be the first of its kind in Canada to combine research, commercialisation and workforce development and training.

Dr Mohsen Mohammadi, Director of the Marine Additive Manufacturing Centre of Excellence and Assistant Professor of Mechanical Engineering at the University of New Brunswick, stated, “This is the first centre of its kind in Canada and we are doing it right here in New Brunswick. Our technology is greener and more efficient than conventional methods and will create high-value jobs here.”

GE Additive refers to its M2 cusing family as the ‘workhorse’ of its metal Additive Manufacturing product portfolio. According to the university, this machine will be used in a variety of research and development areas by Dr Mohammadi and his team, with metal Additive Manufacturing builds being performed at an industrial fabrication and machine shop in Saint John, New Brunswick.