Caltech researchers explore porosity control of copper-based alloys in Additive Manufacturing for spacecraft applications

February 7, 2024

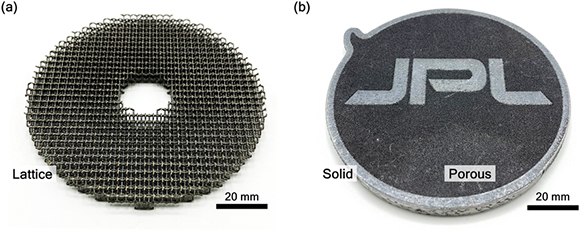

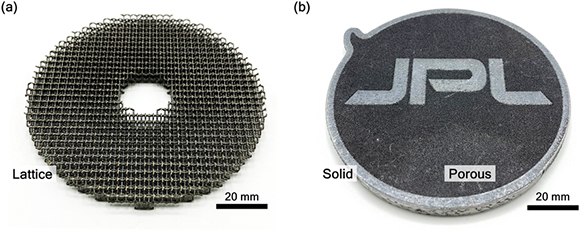

Researchers from the California Institute of Technology, Pasadena, USA, have published new research in the Journal of Porous Materials focused on a novel alternative technique to generate sub-millimetre-scale porosity in Laser Beam Powder Bed Fusion (PBF – LB) Additive Manufacturing using parameter-induced porosity. This technique has been demonstrated for iron, aluminium, titanium, and nickel-based alloys, but has not yet been explored for copper-based alloys.

To establish the requisite relationship between PBF-LB parameters, resultant porosity and material properties, the processing of copper, bronze, and brass samples were explored. Control of porosity was demonstrated with porosity bands of 23.5-47.9% for copper, 0.8-55.3% for bronze, and 8.0-50.2% for brass. Additional electrical and mechanical characterisation highlighted the influence of parameter selection and subsequent porosity on bulk material properties.

The full paper – ‘Porosity control of copper-based alloys via powder bed fusion Additive Manufacturing for spacecraft applications’ – is available here.

Download Metal AM magazine