Bremer Institut investigates Gefertec’s 3DMP arc-based Additive Manufacturing for aerospace

July 25, 2018

The Gefertec arc403 electric arc welding machine installed at the BIAS in Bremen, Germany (Courtesy Bremer Institut für angewandte Strahltechnik GmbH)

Germany’s Bremer Institut für angewandte Strahltechnik GmbH (BIAS), Bremen, and Gefertec, Berlin, are working to qualify Gefertec’s patented 3DMP® wire arc based Additive Manufacturing technology for the production of large structural components, particularly for applications in the aerospace industry. The research is being carried out as part of REGIS, a collaborative project bringing together a number of partners from the aerospace industry, machine manufacturers and other research institutions.

Gefertec recently installed an arc403 3DMP machine at BIAS, where work will be undertaken to ensure homogeneous material properties in the production of titanium and aluminium using the 3DMP process. Funded by Germany’s Federal Ministry for Economic Affairs and Energy, the project is said to offer an important contribution to the removal of the geometrical constraints when additively manufacturing components.

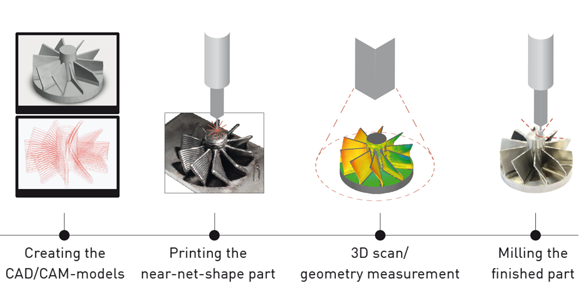

The 3DMP process chain combines the wire arc welding method with CAD data. The part is produced in a fully automatic, controlled manner, followed by quality control scan and final milling (Courtesy Gefertec)

Using 3DMP electric arc-based technology, near-net-shape parts are formed by welding wire feedstock layer by layer. Compared to powder-based Additive Manufacturing, the advantages of the process are said to include a reduction in process times due to high deposition rates and fewer production steps, the ability to produce large-volume components, and high cost-effectiveness due to the use of inexpensive wire as the base material, high material utilisation and low tooling costs.

In order to be able to guarantee consistently homogeneous material properties in parts produced using 3DMP, one focus of the BIAS’s work will be to investigate the influence of heat input and shielding gas concept on the mechanical properties of titanium and aluminium components. Another focus will be on developing an online system for process monitoring of the temperature of the printed material. For this purpose, the emissions-compensated, surface-resolved temperature field measurement developed at the BIAS will be integrated into the machine concept.