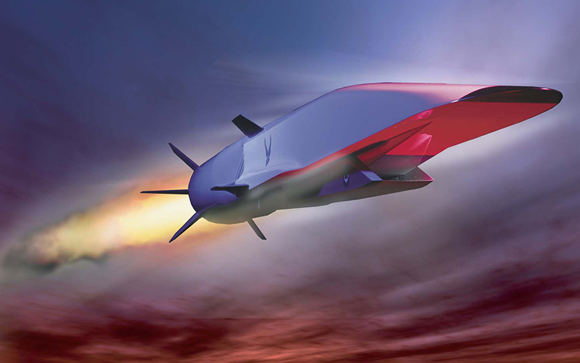

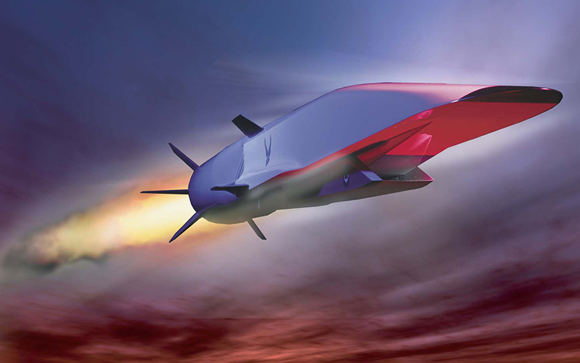

Boeing’s Hypersonics Challenge project to develop build process monitoring and NDE for Additive Manufacturing

September 20, 2022

LIFT, the US Department of Defense manufacturing innovation institute based in Detroit, Michigan, USA, and the US Department of Defense (DoD) have announced the launch of two projects led by Boeing as part of the ongoing Hypersonics Challenge led by the institute.

The first project, with partner Powdermet, Inc., Euclid, Ohio, aims to demonstrate near-net shape manufacturing of metal matrix composite components for hypersonic vehicle demonstrators. These high-performance, high-temperature alloys are expected to drastically boost the capability of components in hypersonic flight environments, which, when combined with near-net shape manufacturing approaches such as Powder Metallurgy, can provide quality mission-critical components that are durable, reliable and rapidly manufacturable.

The second project proposes, with partners RPM Innovations, Inc., Rapid City, South Dakota, and Intelligent Optical Systems, Inc., Torrance, California, to develop and verify a suite of in-situ build process monitoring sensors and non-destructive evaluation (NDE) approaches applicable to laser-based Directed Energy Deposition (DED) Additive Manufacturing for hypersonic applications. Current post-process quality verification is time-consuming and expensive; in-process monitoring is expected to help inform the quality of the build during the process, saving time and expensive metal powders.

“These projects will benefit the entire American manufacturing base, helping spur technology development from material producers all the way up to original equipment manufacturers (OEMs),” stated Austin Mann, Metallurgist/Materials Engineer, Boeing Research & Technology and lead on the first project.

The Hypersonics Challenge was kicked off in 2021 by LIFT and the DoD Manufacturing Technology Program, overseen by the Office of the Under Secretary of Defense for Research and Engineering. The challenge sought proposals on three specific topics critical to the materials science and manufacturing process of hypersonic vehicles.

“Cost-effective approaches to developing hypersonic components that are reliable and rapidly producible are critical to our national security, and these projects will lead us down that path,” added Taisia Lou, Boeing Additive Manufacturing Senior Engineer, and lead on the second project.

Nigel Francis, Chief Executive Officer and Executive Director, LIFT, concluded, “Understanding the materials and how they react to processing so components are near-net shape will help make the development and manufacture of hypersonic components faster, better, and cheaper for the U.S. industrial base, therefore advancing our position in this key technology area, relative to our adversaries.”

The Boeing projects are the final projects awarded through the challenge. Project awards were determined by a team consisting of LIFT and the Department of Defense. Decision criteria include technological merit, technology readiness level (TRL), manufacturing readiness level (MRL), funding requirements, cost-share commitment, ITAR compliance, and LIFT member engagement.