BLT provides Additive Manufacturing components for i-Space’s liquid oxygen methane engine

September 11, 2023

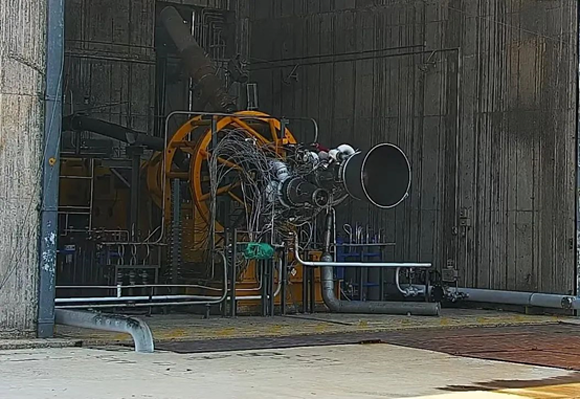

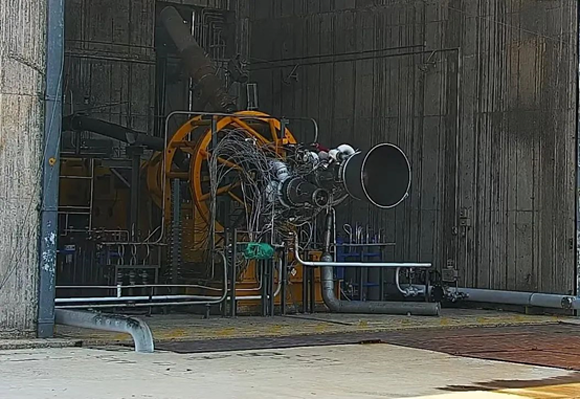

Bright Laser Technologies (BLT), located in Xi’an, China, has utilised its metal Additive Manufacturing to assist Beijing Star Glory Space Science & Technology Company (i-Space) in creating piping and turbopump components for their innovative 100-ton liquid oxygen methane engine, JD-2.

The company reported that on March 1-2, 2023, JD-2 accomplished a significant milestone by successfully completing two semi-system joint tests under real operating conditions. Currently, the engine is undergoing intensive technical research and engineering development, with plans for comprehensive testing and evaluation in the near future.

The use of Additive Manufacturing has met customers’ demands for superior performance, shorter development cycles, and cost-effective solutions for intricate pipeline parts head-on, explains BLT. These components are known for their delicate, thin-walled structures and complex designs and have historically suffered from deformations during production.

Traditional manufacturing methods, which have extended production cycles and wasteful material usage, have proven inadequate. To address these challenges, BLT developed a customised process solution that lowers production costs, accelerates product iteration, and improves the quality and accuracy of parts, benefiting customers.

Turbine pump components are typically divided into two key sections: the screw shell section and the guide vane section. The screw shell section contains an internally designed rotating variable cross-section flow channel, which demands high flow channel surface roughness. The guide vane section comprises multiple blades that require a high degree of blade deviation and surface roughness.

BLT has achieved integrated formation of intricate runners and effective control of deformation during production. The finished part has a high pass rate, dimensional accuracy, and roughness that meet usage needs. The thinnest part of the blade is only 0.3mm, which shortens the production cycle while maintaining quality.

BLT produced the parts using an in-house TC4 and nickel-based superalloy, after conducting a thorough analysis of the parts’ service requirements. The key parameters for part forming were determined based on the process characteristics of the part. After inspection, the strength and performance of the parts met the requirements of the JD-2 liquid engine.

Download Metal AM magazine