BLT premiers industrial-level BLT-S400 metal Additive Manufacturing machine

November 21, 2023

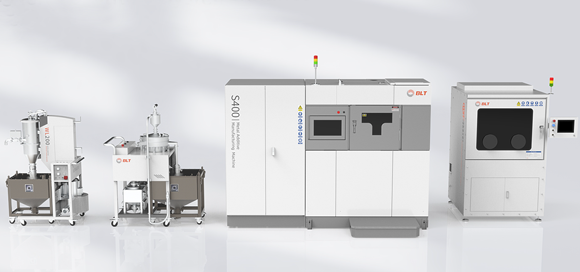

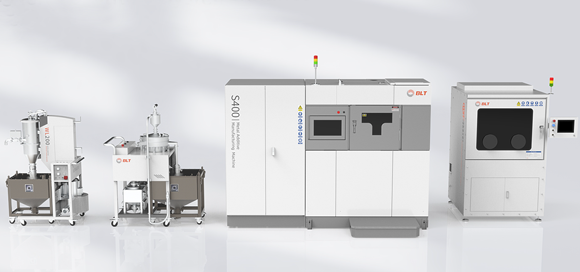

Bright Laser Technologies (BLT), located in Xi’an, China, premiered its industrial-level BLT-S400 Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing machine, its automatic powder circulation system and software solutions at this year’s Formnext 2023.

The BLT-S400’s three-laser configuration makes it suitable for high-volume production of small- and medium-sized industrial parts. Typically, customers with these needs experience high time costs when utilising AM; BLT intends for the BLT-S400 to minimise delivery time and labour costs without sacrificing quality.

The BLT-S400’s new Automatic Powder Circulation System enables the safe transfer, recovery, sieving, and reuse of metal powders within an on-site test laboratory. This facilitates the simple and secure transfer of large volumes of Additive Manufacturing powders from containers to multiple machines, eliminating the risk of spillage contamination, explosion, and contact with workers. The Automatic Powder Circulation System is also able to support multiple Additive Manufacturing machines, acting as a potentially cost-effective investment option that can enhance production efficiency.

Software solutions

Also introduced was BLT-BP, a dedicated slicing software tool for BLT Additive Manufacturing machines. It is reputed to have improved the slicing efficiency for parts that are numerous, large in size, and have complex structures. Even for parts with a 25 G data volume, the required profiling time is 30 minutes.

The BLT-BP has a dynamic powder laying strategy that adapts PBF-LB speed to the part contour, enabling multi-stage automatic speed adjustments. This approach enables both quality and efficiency. Typical parts experience a notable 30% improvement in single-layer efficiency compared to the conventional method.

BLT has also integrated its complete series of AM machine with BLT-MES 2.0, a proprietary intelligent production line management system. BLT-MES 2.0 establishes data connectivity between the planning and execution tiers within the Additive Manufacturing landscape. This system offers comprehensive end-to-end digital manufacturing solutions, encompassing product management, project planning, intelligent scheduling, manufacturing execution, data IoT integration, statistical dashboards, online reporting, and more.

Download Metal AM magazine