Bloodhound LSR, featuring metal additively manufactured parts, reaches 628 mph in speed testing

February 4, 2020

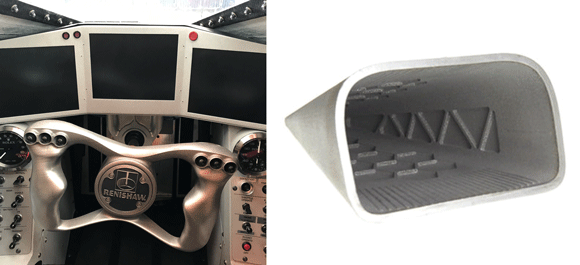

The Bloodhound LSR, a supersonic car incorporating a metal additively manufactured titanium nose tip and steering wheel produced by Renishaw, achieved a speed of 628 mph (1,011 km/h) during high-speed testing at the Hakskeen Pan track in South Africa. The team behind the Bloodhound LSR, formerly Bloodhound SSC, are working towards breaking the world land speed record, set over twenty years ago.

Renishaw began working with the Bloodhound project in 2013 when it became a sponsor, and has since provided its Additive Manufacturing expertise to design and manufacture parts for the supersonic car.

The titanium steering wheel is designed specifically to fit the hands of Andy Green, assisting him when driving the car. The Bloodhound’s nose tip, again manufactured from titanium powder, is a strong, lightweight component, capable of dealing with the extreme loadings that occur when the car is at high speeds.

“Reaching 628 mph in South Africa was an incredible achievement for Bloodhound and it was exciting to see Renishaw’s technology being a part of it,” commented Chris Pockett, Head of Communications at Renishaw. “Additive Manufacturing gave us the freedom to design the nose cone and steering wheel specifically to undergo the extreme forces involved in the land speed attempt, which would’ve been difficult with traditional manufacturing methods.”

The Bloodhound team is now working through its plan of high-speed testing, followed by its attempt to set a new world land speed record in 2020/21. The current land speed record of 763.035 mph (1,227.985 km/h) was set in 1997 by the Thrust SSC car, also driven by Andy Green.