AutoSmooth project looks to develop automated post-processing in ColdMetalFusion series production

October 20, 2023

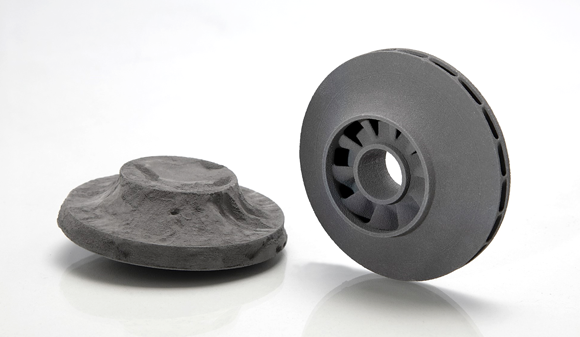

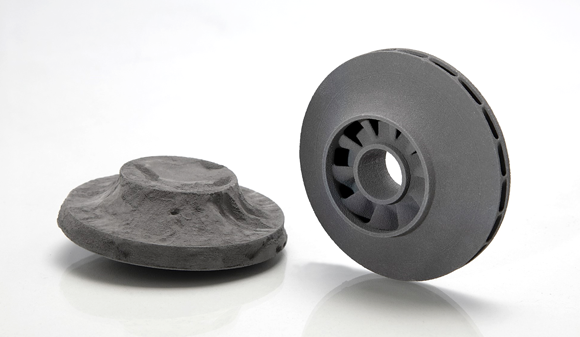

Germany’s Headmade Materials GmbH in collaboration with AM Solutions, a brand of the Rösler Group, and Neue Materialien Bayreuth GmbH, have launched the AutoSmooth project to develop a continuous process chain for the ColdMetalFusion (CMF) technology from powder to ‘smoothed’ component.

CMF technology already allows users to manufacture metal components in high-volume series production. However, to fully maximise the potential of this series production, a further development is still needed: the automation of the unpacking of the parts and their subsequent surface processing.

The main objective of the AutoSmooth project is to create a fully automated process chain specifically designed for unpacking and surface treatment of ColdMetalFusion components within the next three years. Headmade Materials, AM Solutions, and Neue Materialien Bayreuth look to combine their respective expertise to successfully overcome this challenge.

“From our perspective, the key to industrial production with low scrap rates for the entire industry lies in component handling. Through the cooperation in the AutoSmooth project, we will reach a new level here. In order to exploit the full potential of additive series manufacturing, it requires the automation of unpacking and surface processing,” shared Christian Staudigel, Co-CEO of Headmade Materials. “CMF technology has already laid the foundation for this, and now we will take the next step toward a fully automated solution with our partners.”

Dr Till Merkel, Division Manager Technology at Rösler Oberflächentechnik GmbH, concluded, “Our many years of experience in surface processing combined with the high scalability of ColdMetalFusion and the research know-how of Neue Materialien Bayreuth will revolutionise additive metal series production.”

Download Metal AM magazine