Automatic 3D simulation of 2D drawings used to determine suitability for Additive Manufacturing

November 13, 2023

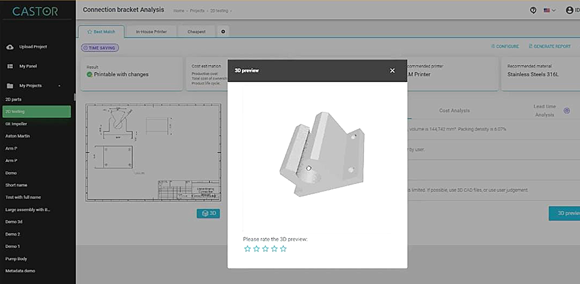

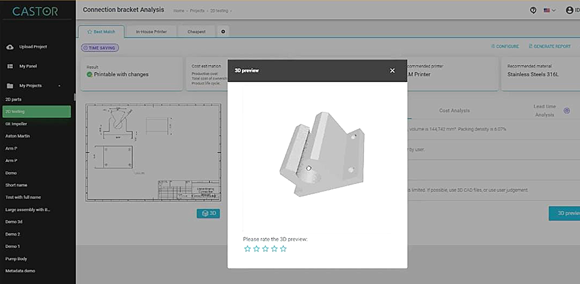

Castor Technologies Ltd, based in Tel Aviv, Israel, has introduced new software that automatically visualises 3D parts from 2D drawings. Once a 2D drawing is uploaded, Castor’s software allows users to simulate a 3D view, providing a comprehensive analysis of its suitability for Additive Manufacturing. The software is also expected to provide improved estimations of cost, sustainability, lead time, and supply chain advantages.

Opening new opportunities

The new functionality provides a fast Geometric Analysis, which factors in material properties, cost-effectiveness, and digital supply chain advantages, greatly simplifying the decision-making process. While it doesn’t eliminate the need for a 3D file, it allows engineers to identify parts suitable for Additive Manufacturing, speeding up the evaluation process and shortening the time-to-market for AM projects.

“The new capability introduced by CASTOR will be a game-changer for engineers, significantly reducing the time and effort required to qualify AM parts. This tool will eventually enable engineers to expedite the identification of parts suitable for 3D printing and allocate their valuable skills to more strategic tasks,” stated Omer Blaier, co-founder & CEO of CASTOR. “With this innovation, we aim to transform the landscape of Additive Manufacturing and make it even more accessible for companies relying on 2D PDF drawings in their manufacturing processes.”

Identifying suitable parts for Additive Manufacturing at scale

Castor’s software allows for the automatic extraction of product manufacturing information (PMI) from PDF files of 2D drawings. It calculates the size, volume, and complexity of parts, and generates a visual 3D simulation based on the dimensions derived from projected views.

Using this information, it suggests the additive manufacturability of parts, recommends optimal technology and materials, and performs a financial analysis of Additive Manufacturing compared to traditional manufacturing. It exports useful information and insights, both as a formal PDF report and a raw data Excel sheet.

The quick results guide engineers on which parts to purchase or to further explore their 3D CAD files. Once the selected files are in a 3D format the software, which is available on cloud and on-premise, can also deliver recommendations for re-designing parts for Additive Manufacturing – such as part consolidation and weight and reduction. The advanced capabilities enable quick assessment of a part’s likelihood to failure, using a unique, tailored to AM, Finite Elements.

Download Metal AM magazine