Authentise launches Guidelines feature for aMES

October 31, 2022

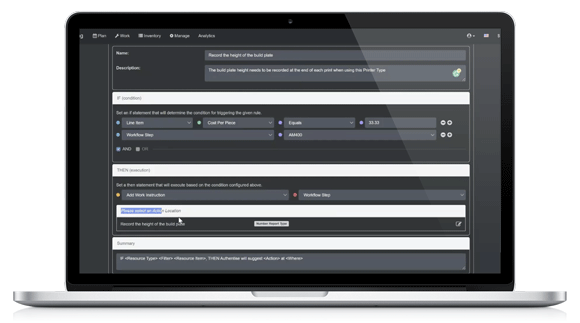

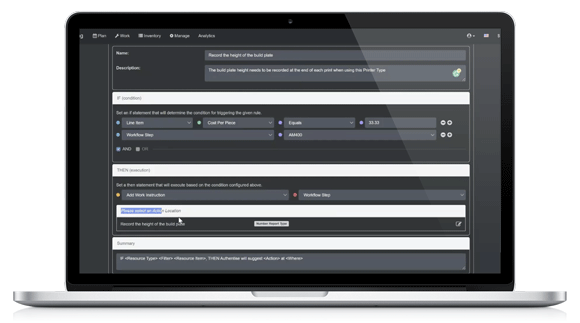

Authentise, Philadelphia, Pennsylvania, USA, has released Guidelines, a new set of features for users of aMES, the company’s workflow engine for Additive Manufacturing.

Guidelines enable users to formulate if-this-then-that rules that use any type of engineering or production data as input. These rules then trigger suggestions at any point in the process. With Guidelines, a combination of machine sensor feedback, geometry features, or QA measurements, among others, can be used as triggers to suggest changes in behaviour or parameters that will ensure a more successful and sustainable production outcome. These suggestions are delivered to the user when required, during the engineering stages or in production.

“If-this-then-that rules are not new in robotic process automation but have yet to be used successfully in the manufacturing context beyond basic principles such as quoting,” stated Andre Wegner, CEO of Authentise. “We realised their broader power almost immediately and spent the last 10 years building, with aMES, a contextual data engine capable of harnessing them. They represent a break from more prescriptive tools, such as our workflow generator. This permissive approach makes them the ideal channel to ensure that rules are followed while giving experienced engineers and operators the latitude to make the decisions necessary on a case-by-case basis. We’re fortunate to work with partners such as ASTM to ensure that this novel framework is not only filled with tribal knowledge present within each organisation but uses existing standards as a starting point.”

Dr Martin White, Head of Additive Manufacturing Programs – Europe at ASTM Additive Manufacturing Center of Excellence, commented, “There is great value in considering how Standards can be fully applied in the digital world. Guidelines has the potential to evolve how Standards can be accessed and embedded in manufacturing processes with increased accessibility. We’re excited to work with Authentise to ensure that users can access applicable standards in this way. Not only does this have the potential to ensure greater compliance but doing so in a digital framework allows our partners to potentially reduce audit costs too.”

The delivery of Guidelines was supported by Innovate UK’s Transforming Foundation Industries challenge under the SAMRCD grant, under which Authentise and ASTM collaborate with Photocentric, MPI and TWI.

Simon McCaldin, VP of Open Innovation at Authentise, said, “Guidelines very intentionally puts the power to make decisions back into the hands of those on the frontlines, whom most of the Industry 4.0 movement has so far marginalised. We believe this will, in the medium term, also help us deliver more acceptable forms of Artificial Intelligence to the industry. aMES has now reached the level of maturity necessary to capture the data that can drive advanced machine learning systems.

McCaldin added, “However, operators are rightly cautious of adopting systems operating as a black box with no oversight. Guidelines represent a more transparent delivery method and will increase real-world acceptance, while ensuring compliance with process control procedures. Now that it is built, Authentise will not monopolise the channel that Guidelines represents. We’re committed to keeping this new delivery method open to all smart algorithms providers and are grateful to Innovate UK for believing in this approach and supporting the creation of Guidelines.”