Authentise and Microsoft collaboration puts automation in the hands of operators

March 28, 2019

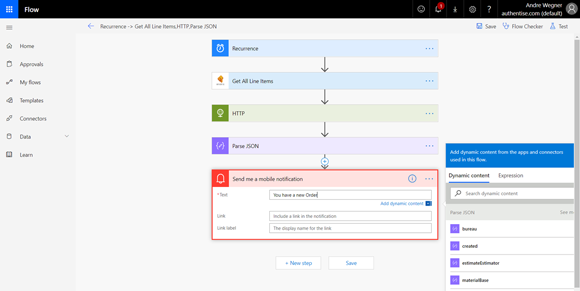

An example workflow within Microsoft Flow (Courtesy Authentise)

Authentise, Philadelphia, Pennsylvania, USA, a developer of data-driven workflow tools for Additive Manufacturing, has agreed to a multi-year collaboration with Microsoft to utilse Microsoft Azure and integrate Authentise’s workflow management system into Microsoft Flow. The integration with Flow, which is set to go live this week on the Microsoft Flow Gallery, gives operators directly involved in Additive Manufacturing quoting, production and analytics processes the opportunity to create their own automations without any coding knowledge.

Flow allows operators to connect Authentise’s data with third party applications such as Microsoft Office 365, Quickbooks, text messaging, email and more, by simply dragging and dropping the operations into place. In doing so, they can create custom alerts, dashboards, and other workflow automations to further increase transparency and efficiency in their Additive Manufacturing operations.

Andre Wegner, CEO of Authentise, stated, “We’re delighted to be working with Microsoft to put power into the hands of operators. Our work has shown us how creative those involved with additive production are, and how that ingenuity is often stifled within their operations. Yet, there are many ways in which they could improve their daily operations with zero risk. Thanks to this collaboration, we are giving the power to make those changes to anyone, no matter their background.”

Werner Stapela, Global Head of Additive Design & Manufacturing at Danfoss, an Authentise customer, commented, “Danfoss’ additive operations have quadrupled over the last year. Working with Authentise has helped us manage that workload, but every operator has slightly differing requirements and preferences. Giving individuals within any part of the additive workflow the opportunity to craft their own automations is the only way to ensure that the production processes is working as smoothly as possible. We’re delighted that Authentise and Microsoft have recognised this and are providing our staff with the necessary tools and integrations.”

In addition to the integration with Flow, Authentise is also switching its existing customers to Azure. Diego Tamburini, Principal Manufacturing Industry Lead for Cloud Commercial Communities at Microsoft, stated, “Microsoft is pleased to help Authentise empower manufacturing workers by enabling them to create their own business workflows on the Microsoft cloud. By adding manufacturing-specific connectors to the Microsoft Flow gallery, Authentise is unlocking the workers’ creativity so they can improve the efficiency of their own work.”

“With fifty-four regions across the globe delivering services to 140 countries, Microsoft Azure is uniquely positioned to help manufacturers meet their compliance obligations including ITAR and GDPR. While Manufacturers may have once shied away from the cloud, they are no longer doing so,” he concluded.

In a background essay on the advantages of enabling operator-driven automation, Andre Wegner highlighted how putting process automation into the hands of workers could help to counteract the “confrontational relationship” some operators have with technology, fueled by fears and discussions of automated systems as a ‘replacement’ for workers. Instead of pitting workers against technology, he stated, the industry can benefit from “uniting them in collaboration with it.”

“High-handed talk of ‘replacing’ workers displays a radical misunderstanding of future needs,” he continued. “World markets, driven by fast information flows and instant access to digital products, demand a level of agility that manufacturing companies can scarcely imagine, let alone deliver. We need to drastically reduce the time and cost to deliver ideas to market, and be able to adjust production in real time to correspond to shifts in demand. We can only accomplish this if we move away from the planning framework currently used and towards a model of inherent and constant change.”

Wegner stated that many companies do not understand the potential of automation, with only 5% of occupations currently automated, and 45% of those operator tasks which are currently performed manually having the potential to be automated. “Identifying those tasks among billions is a nearly insurmountable endeavour to be undertaken from the top down,” he explained. “To uncover the true potential in our processes, we need to work with the experts who perform these tasks – not against them.”

Authentise was founded in 2012 at the Singularity University in California, USA. Its products include the Additive Accelerator, a workflow management engine connected to Additive Manufacturing machine data, and 3Diax, a platform of Additive Manufacturing related software modules. These tools are currently being used by companies involved in AM R&D, prototyping and production to reduce effort and cost, improve traceability and transparency and deliver quality.