Authentise acquires Elements Technology to bring data-driven flexibility to manufacturing

February 10, 2022

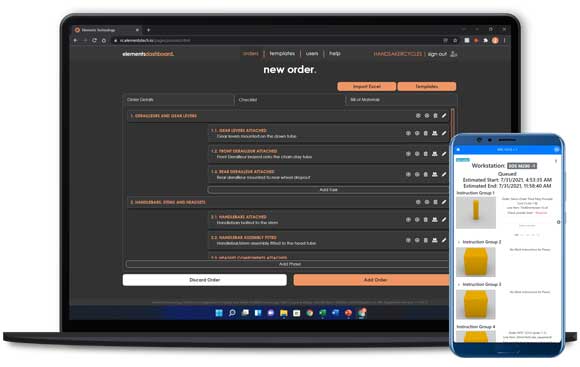

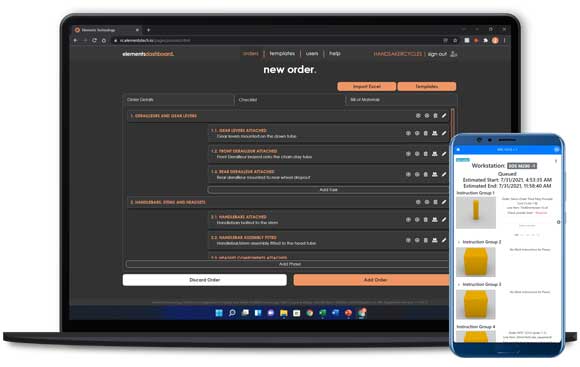

Authentise, Philadelphia, Pennsylvania, USA, reports that it has acquired all the assets of UK-based Elements Technology, a provider of self-serve workflow tools for manufacturing. The acquisition will enable customers to access connected workflow management solutions used by leading Additive Manufacturing companies to manage their lot-size one operations efficiently. As part of the transaction, Elements’ team will join Authentise.

“Elements is the perfect addition to the Authentise portfolio,” stated Andre Wegner, CEO of Authentise. “Like Authentise, Elements have been laser focused providing manufacturing operations with the flexibility they need in the post-pandemic world with the efficiency that data enables in the 21st century.”

“Elements provides customers with a unique self-serve tool for all types of manufacturing operations, to quickly create, capture and access repeatable shop floor processes,” continued Wegner. “Delivering intelligent production planning and scheduling, and real time views of production, customers can track orders, like they’re paying for coffee. These exciting services will become a key part of the combined Authentise portfolio.”

Authentise notes that even before the acquisition it was able to deliver significant efficiency savings, reducing order management times by 80% and manufacturing preparation times reduced by more than 95%, citing its work with Boeing Additive Manufacturing as an example.

“Our goal together is to bring flexibility and responsiveness benefits like these, typically associated with Additive Manufacturing, to a broader manufacturing audience. With our diverse experiences we believe we will be able to rapidly accelerate towards our joint mission of delivering end-to-end transparency, reliability, and efficiency to manufacturing operations using data. We’re delighted to welcome the Elements team and customers on board,” Wegner added.

Joe Handsaker, CEO of Elements Technology, commented, “The real story of Industry 4.0 has yet to be written. The last twenty years have been wasted focusing on predictive maintenance and analytics, which have yielded very little Return on Investment. It’s time to refocus on what’s core to manufacturing: the worker. Supporting them with data and modern tools gives us more context in manufacturing and allows us to drive better quality, insight, and completely new business models. If nothing else, the pandemic has shown that a radical rethink of the way things are made and delivered is necessary. We’re delighted to have found a partner that understands that and are excited to build a better future, together.”