Aurora Labs produces its first metal powders for Additive Manufacturing

June 12, 2018

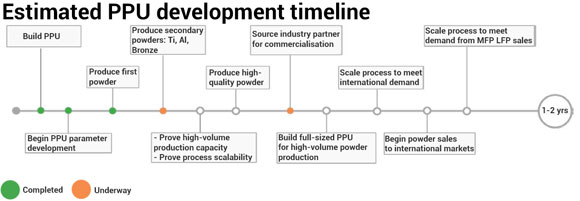

Aurora Labs’ estimated PPU development timeline for the next 1-2 years (Courtesy Aurora Labs Ltd)

Aurora Labs Ltd, Bibra Lake, Western Australia, has produced the first batch of laboratory test-scale powder from its prototype powder production unit (PPU). According to the company, the prototype PPU is intended to test and demonstrate its technology for producing high-quality powders for use in metal Additive Manufacturing.

It is reported that Aurora’s process allows AM-suitable metal powders to be produced at substantially lower costs than is possible with existing processes. Now, the company will seek to prove its capacity for high-volume powder production, confirming yields and quality parameters.

David Budge, Managing Director, Aurora Labs, stated, “The result for producing our first powder is an outstanding achievement for the company. The process of going from concept through to patenting and production of a product is at times an arduous one, but the team has worked extremely hard, determined to achieve this outcome.”

“Seeing a result where we have produced high-quality spherical powder where almost all of the powder produced is within a very narrow size range is a remarkable result and one that the company and its staff can be proud of,” he continued. “This development opens up significant new opportunities for the company. We hope that this result will pave the way for Aurora Labs to become a global player in a highly compelling industry.”

In addition to its powder development efforts, Aurora manufactures the S-Titanium Pro small format metal Additive Manufacturing machine. Priced at around US $50,000, this is thought to be one of the most affordable metal AM systems on the market.

Aurora is also continuing to develop its large format Additive Manufacturing technology (LFT), and has reportedly produced a significant number of parts and shapes with its LFT prototype. Recently, the company stated that it has achieved the goal of additively manufacturing simple parts at market speed (i.e. a rate comparable to existing technologies on the market).

It is intended that the powders produced from Aurora’s PPU will support part of the projected high utilisation of consumables from the company’s large format printers.