Aurora Labs LFT targets metal Additive Manufacturing build speeds

September 18, 2018

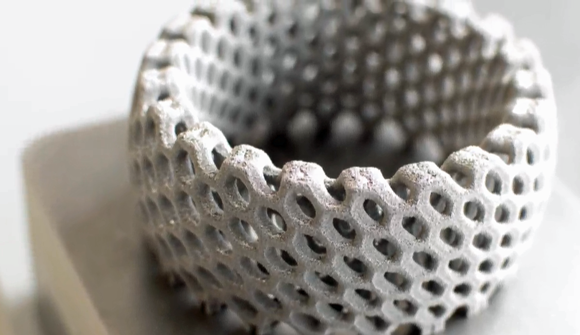

The first build completed using Aurora Labs’ Large Format Technology (Courtesy Aurora Labs)

Aurora Labs, Bibra Lake, Western Australia, reports that initial builds using its Large Format Technology (LFT) for metal Additive Manufacturing achieved a build speed equivalent to 662 g/h, or 15.88 kg/day, claiming that this exceeds the ‘market speed’ by a factor of eight. According to the company, this indicates that, once its full-sized Rapid Manufacturing Printer (RMP) is fully built, its targeted build speed of 1000 kg/day could be achievable through scaling.

The initial tests were carried out on the Alpha model, Aurora Labs’ first fully-functioning LFT machine, for the production of a complex metal part including curves and internal structures in commercially pure titanium (Cp-Ti). The system has a build envelope of 200 x 200 x 200 mm, and both the envelope and build speed are expected to be scaled up to create the company’s first RMP production units.

Aurora Labs defines ‘market speed’ as the standard speed of metal AM machines which are currently available on the market, are of comparable size to the Alpha model and are able to build parts in Cp-Ti. According to the company, its research has shown the standard market speed to be 81.7 g/h, or 1.96 kg/day.

David Budge, Managing Director, Aurora Labs, stated, “Possibly more than any other step in Aurora Labs’ history, this one is the most important, as it proves out at a fundamental level the potential for this technology to revolutionise the metal manufacturing market. The nature of the Large Format Technology and its ability to be scaled allows us to understand at this stage in the development cycle the potential for this technology to be able to print at our target rate of 1000 kg/day.”

The company expects to have the pre-production model of its RMP ready for sale to an industry partner before the end of 2018. It will now focus on scaling the technology and increasing build speeds further to the targeted 1000 kg/day.