ASL commissions new gas atomiser for AM and MIM powders

September 25, 2019

Atomising Systems Ltd. (ASL), Sheffield, South Yorkshire, UK, has further expanded its capacity with the installation of a new 400 kg batch gas atomiser aimed specifically at the Additive Manufacturing and Metal Injection Moulding (MIM) powder markets. ASL is a specialist in the production of stainless steel powders, and also produces low-alloy and Ni-based alloys.

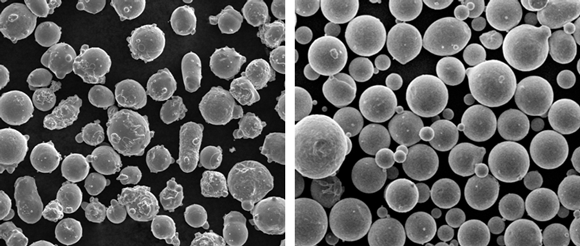

The atomiser was designed in-house and is reported to be equipped with ASL’s proprietary anti-satellite and hot gas system, resulting in powders that are low in satellite and high in flowability. The new atomiser can produce high yields of MIM and/or AM powders, enabling ASL to continue to serve its expanding AM and MIM customer base.

“The addition of another atomiser, along with the associated sieving and classification equipment, means that we are able to keep pace with the growth of our existing client base and the requirements of new clients, especially in the AM and MIM sectors,” stated Paul Rose, Commercial Director. “In these sectors, the benefits of ASL’s anti-satellite technology are clearly recognised through the excellent powder shape and flow properties.”