ArcelorMittal and Additive Industries look to large spare part printing for steel industry

April 2, 2020

ArcelorMittal, the world’s leading steel and mining company, and Holland’s Additive Industries joined forces in 2017 to explore the opportunities of Additive Manufacturing for the steel industry. At the time, the Additive Manufacturing of spare parts was seen as a practical option, as it offered on-demand, on-location production, reducing the need for stock. It was hoped this may shorten the production cycle as well as affording flexibility to ArcelorMittal plants.

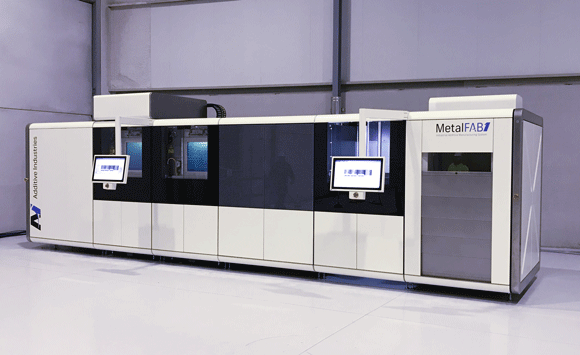

ArcelorMittal has since utilised Additive Industries’ MetalFAB1, an AM production system with a build volume of 420 x 420 x 400 mm, for the production of large steel spare parts for steelmaking or mining operations. The system is said to be one of the the safest on the market, in-line with ArcelorMittal’s focus on operator safety as well as its environmental goals, since the system recycles all material and generates hardly any production waste.

“We are proud to work together with ArcelorMittal, jointly driving the business case for 3D printed parts in the steel industry,” stated Harry Kleijnen, Key Account Manager Additive Industries. “ArcelorMittal’s typical applications have enabled us to further adapt the MetalFAB1 system to print high density, high volume parts. We are looking forward to expanding the range of applications and materials in this intense and strong collaboration”.

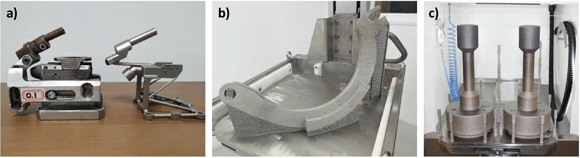

Since the installation of the first metal AM machine in ArcelorMittal’s R&D facilities, several AM spare parts have already been used, while others are still running in ArcelorMittal facilities (see Fig. 2).

“Innovation and market leader ArcelorMittal have helped us to stress-test our MetalFAB1 system for critical spare-part production,” added Daan AJ Kersten, Co-founder and CEO Additive Industries. “This enabled us to expand our experience to the steel industry from our main application markets in aerospace and automotive. It has become clear that metal 3D printing is a serious alternative for a large variety of cast parts.”

Steelmaking operations are usually faced with very challenging and demanding conditions for their spare parts. During the initial stages, the most challenging aspect faced was to achieve these requirements both for quality as well as for the size of the components, limiting the potential uses of spare parts. The last two years of collaboration have enabled those involved to improve both quality and reliability, as well as achieving an up to fourfold increase in the size of components.

Due to this improvement, the number of applications increased from small-size part consolidation applications (see Fig. 2a), to applications where large, complex, functional and strong parts are required (see Fig. 2b and c).

“Additive Manufacturing is an exponential technology, moving very fast. Our collaboration with Additive Industries is a clear demonstration of our ability to remain at the cutting-edge of this technology: we started by printing small specimens and have now progressed to large size and complex parts,” commented Jose López Fresno, Head of the Additive Manufacturing department, ArcelorMittal Global R&D in Avilés, Spain.