AP&C partners with Canada’s Research Council on advanced image analysis for metal powders

August 17, 2018

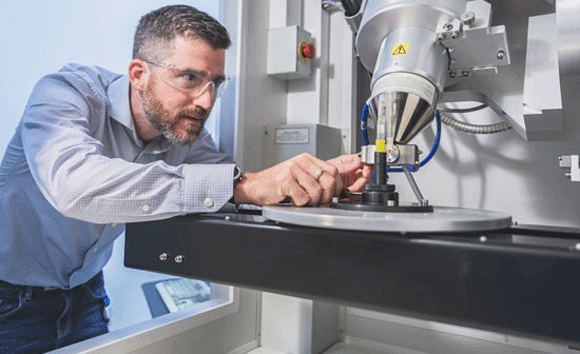

Dr Fabrice Bernier, a researcher at the NRC, analyses powders used in Additive Manufacturing (Courtesy National Research Council of Canada)

The National Research Council of Canada (NRC) and AP&C, a GE Additive company based in Montreal, Quebec, Canada, have developed a way to test the quality of powders used in Additive Manufacturing using x-ray micro-computed tomography (micro-CT) and 3D image analysis. According to the partners, this could lead to the production of stronger, cleaner, safer and more reliable additively manufactured parts for aerospace and medical devices.

The testing method developed allows for the detection of very low concentrations of foreign particles in powders. Using x-ray micro-CT and 3D image analysis, each individual foreign particle is visualised and its size, brightness and overall concentration measured. In situations where cross-contamination is a concern, the technique is said to be more sensitive and discriminating than current methods available for chemical analysis.

The testing method was validated using titanium powders intended to be used in aerospace parts, in collaboration with industrial partners. The NRC and AP&C are now said to be expanding its capabilities to cover other materials and metals, such as nickel alloys. The method could be especially useful in the qualification of recycled powders in safety-critical applications.

The partners stated that they are cooperating further on improving and developing metal powder characterisation methods that are better adapted to the specific needs of the metal AM industry. In addition to detecting foreign particles using x-ray micro-computed tomography, the NRC is currently working on analysing the flow of metal powders during the AM process by measuring how spherical and porous particles are.

Louis-Philippe Lefebvre, Powder Forming Team Lead, Medical Devices Research Centre, NRC, stated, “We hope this new method will support the industrial adoption of 3D printing and ease its implementation in highly regulated environments such as the aerospace and medical devices industries. As a leader with over thirty years of experience in Powder Metallurgy and Additive Manufacturing, the National Research Council is pleased to have joined forces with AP&C to improve the reliability of the manufacturing process and metal powder behaviour.”

“The competitiveness of 3D printing relies heavily on the capability of machine users to recycle their powders; however, the industry is concerned that foreign particles will be introduced in the feedstock as the powder is recycled,” added Frederic Larouche, Executive Vice President & Chief Technology Officer, AP&C. “The method we are developing could help confirm that the feedstock maintains the utmost cleanliness during processing. Leveraging our complementary research and development competencies should help speed the development of 3D printing technologies.”

AP&C has been collaborating for more than six years with the National Research Council of Canada on developing and characterising titanium and nickel superalloy powders for AM, Metal Injection Moulding and other Powder Metallurgy processes. “Our partnership with the National Research Council, a recognised research organization with deep expertise in Powder Metallurgy and materials characterisation, is supporting Advanced Powders & Coatings’ growth and allows us to offer better-integrated solutions to our partners,” concluded Larouche.

www.ge.com/additive/additive-manufacturing/materials/apc-homepage