AMSIS releases updated Genesis 4 build-job preparation and simulation software

November 22, 2023

Amsis, based in Bremen, Germany, has released the latest version of its Genesis software, Genesis 4 Beta. This software offers new features for both equipment manufacturers as well as users of metal Additive Manufacturing machines to improve laser exposure quality and minimise support structures. The potential for cost optimisation for users of Laser Beam Powder Bed Fusion (PBF-LB) technology is reported to be between 10-30%, depending on the application. The Genesis 4 modules can be integrated into machine software.

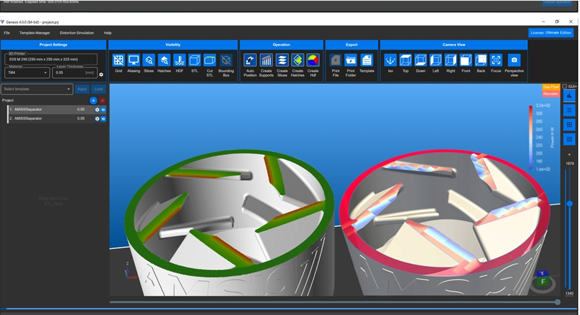

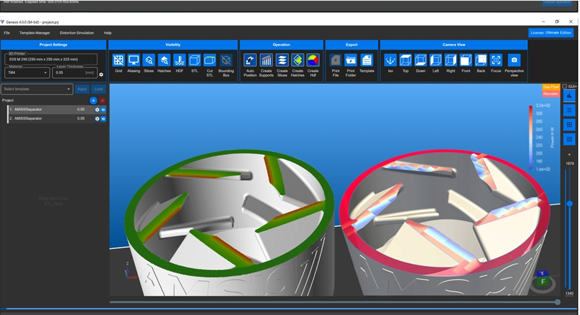

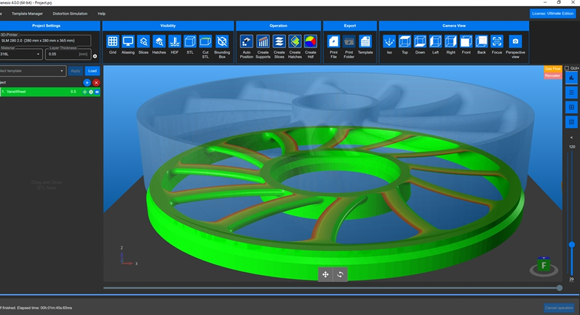

Genesis 4 supports end users along the entire process chain of build-job preparation: importing of STL data, optimal placement and nesting of parts in the build space, generation of support structures, slicing, hatching and exporting the build-job. The USPs of Genesis 4 pointed out by the company are the simulation-based functionalities: automatic identification of the overheated zones of a part, automatic reduction of the energy input depending on the overheating intensity, and the hatching design of the optimal orientation and sequence of the exposure paths.

Fast thermal simulation as a core technology

Thermal simulation within seconds for small parts and up to just a few minutes for large parts enables the precise identification of overheated zones of a part and a quantified depiction of the overheating intensity (criticality). On the basis of the calculated overheating intensity, a specific reduction of the energy input in the overheated areas is carried out. Using the results gained from the thermal simulation, hatching strategies for the optimal orientation and the sequence of the exposure paths are also realised.

Together, all of the above simulation-based functionalities result in an optimised thermal management of the overheated part zones, a reduction in support structures, as well as an improvement of the mechanical material properties and quality of the part surfaces.

Prof Dr-Ing Vasily Ploshikhin, Managing Director of AMSIS, explained, “Optimised thermal management increases the process stability of the 3D part structure. End users can significantly increase the performance of their existing machines with Genesis 4 and print higher quality parts with either minimal or no support structures.”

Genesis 4 versions: Classic or Innovative

As stand-alone software, Genesis is available in two versions: Classic and Innovative. Genesis Classic, the basic version, has all the functionalities for build-job preparation. It can be used as an inexpensive alternative to established software tools for build-job preparation, such as Magics from Materialise or Netfabb from Autodesk. In the advanced version, Genesis Innovative, classic build-job preparation is complemented with simulation-based functionalities. These include the fast-thermal simulation module to identify overheated zones, the module for simulation-based local parameter adaptation and the hatching module for designing the optimal orientation and sequence of the exposure paths. The two software versions currently run via native machine formats on AM machines from Aconity3D, DMG MORI, EOS and SLM Solutions.

A modular system for easier integration into other software tools

Genesis’ modular structure makes it possible to integrate the individual software modules as parts into other software tools. This is meant to be particularly beneficial for manufacturers of Additive Manufacturing machines. Integration of the thermal simulation and parameter adaptation modules into the machine software will make it possible to automatically reduce the laser power of AM machines in hotspots and thereby avoid overheating. An additional use of the module for optimised hatching regarding the orientation and sequence of exposure paths makes it a quick and inexpensive way for machine manufacturers to access technology that minimises support structures.

Improving cost by reducing support structures

Genesis 4 users have the opportunity to significantly reduce support structures with their existing AM machines or to build support-free parts, meaning there is no need to invest in hardware such as new AM machines. Depending on part geometry, using Genesis 4 currently reduces support-free overhangs of 45° down to 20° for titanium alloys and down to 25° for steel, Inconel or aluminium.

Build-job preparation with Genesis 4

Genesis 4 offers various automated tools to prepare for a build-job. First, STL data is imported and nesting configuration on the build plate in the build chamber is carried out. The parts are nested in the building chamber according to the user’s desired criteria (e.g. minimal build time or minimal support structures). After the necessary support structures have been generated, fast slicing of the individual layers of the part is realised. This is then followed by a fast-thermal simulation to identify hotspots, as well as a simulation-based hatching for the optimal orientations and sequence of the laser paths. In the following step, energy input is automatically reduced in the overheated zones. Finally, all build-job parameters can be saved in a template manager to ensure a repeatable process.

Automatic identification instead of manual settings

With Genesis, the simulation-based identification of overheated zones is completely automatic. This means the manual setting of down-skin areas that is practiced today, based on the user’s experience, can be eliminated. The size of the identified overheated zones and the level of overheating intensity automatically change depending on material properties and local peculiarities of the part geometry. This results in a major benefit compared to conventional manual setting of the down-skin areas, which is currently carried out without consideration of local geometries and material properties.

Optimised thermal management

Planning of the support-minimised build-job is all done during the pre-processing phase. Using fast thermal simulation, hotspots in the part are identified within seconds or minutes and the energy input in these zones is modulated locally. The energy input is usually adjusted by reducing the laser beam power locally or by increasing the scan speed. The localised reduction of heat input in the hotspots is possible for every common hatching pattern (e.g. for conventional stripe exposure). The optimisation of energy input works even more efficiently when using new, innovative 3DF hatching patterns generated from Genesis.

New 3DF hatching patterns reduce crashes with the recoater

The angle between a scan vector and the edge of an overhang is very important for support-minimising technology. The smaller this approach angle is, the more advantageous for the application. Conventional hatching patterns only provide for two possible orientations of the scan vectors (e.g. 0° and 90° to the preferred direction of a stripe) and thus represent hatching patterns with two degrees of freedom (2DF). In the case of conventional hatching patterns, the angle between the scan vector and the edge of the overhang can be up to 90°. This orientation leads to a greater deformation of the overhang edge in the build direction and, as a result, to an increased risk of a crash between the part and the recoater.

In addition to all conventional hatching patterns, Genesis 4 also offers new so-called 3DF hatching patterns, such as hexagonal patterns. Deploying hexagonal 3DF hatching patterns makes it possible to reduce the angle between the scan vector and the edge of the overhang down to 30°. These innovative 3DF hatching patterns from Genesis enable better adaption of scan vectors to the geometry of the critical overhangs of a part. This leads to a reduction in the deformation of unsupported overhang edges in the build direction and thus to a reduction in possible impacts of the built part with the recoater.

Prof Dr- Ing Ploshikhin shared, “Thermal simulation within seconds to identify hotspots and a simulation-based reduction of the energy input in these critical zones with Genesis 4 enable hatching that minimises support structures with all conventional hatching patterns. This support-minimising strategy works even more efficiently when using innovative 3DF hexagonal hatching patterns from Genesis.”

Continuous parameter adaptation

With conventional hatching strategies, the critical down-skin zones are exposed as separate areas. The process parameters in the internal area of the part and in the down-skin area are usually different. This leads to a sharp overhang and thus to increased porosity in the core-to-skin overhang areas. With Genesis 4, there is a continuous reduction of energy input in overheated zones. No sharp transition areas are formed, reducing the risk of porosity in the overhang areas.

Optimal sequence of scan vectors prevents build-up of loose powder

With conventional hatching strategies, it cannot be avoided that scanning starts in loose powder. This leads to poor surface quality and also prevents a support-free part build. However, with Genesis 4, the sequence of the scan vectors is controlled based on the simulation. The optimal sequence of scan vectors results, among other things, to a significant reduction in the undesirable start of a scan vector in loose powder.

Greater cost effectiveness in the process chain

The use of Genesis 4 provides support along the digital process chain of a 3D build-job during the pre-process, in-process and post-process phases. Cost advantages are reported to occur in three dimensions:

- A build-job with minimised support structures decreases manufacturing costs

- The build time for the build-job decreases

- Material consumption decreases. Post-processing costs of a part are reduced.

The aim here is to have to remove fewer support structures, to increase the powder recycling rate and shorten surface treatment time. Another special feature is the easy powder removal through the use of so-called arc supports.

Genesis 4 scope of features compared to the previous Genesis 3 version

Genesis 4 offers users many new tools intended to improve process and part quality. The basic functionality – fast thermal simulation – runs even more quickly compared to the previous Genesis 3 version. Thanks to visualisation, this thermal simulation can now be viewed by the user. Another module enables automatic reduction of the energy input in the identified hotspots. This occurs, for example, through reduction of the laser power.

With the help of a new orientation module, optimal orientation can be found for the minimal quantity of support structures or for a decrease in the build time of the part. With the distortion simulation module, a preform part geometry can be calculated in order to achieve maximum geometric accuracy despite distortion. The new functionalities are rounded off by the AI-supported module for analysing process monitoring data. This module enables users to identify and classify defects in printer-specific photographs. The locations of the identified defects are overlaid with the hatching pattern used in order to ensure better analysis of the cause of defects.

Prof Dr- Ing Ploshikhin, Managing Director AMSIS, added, “Genesis 4 was designed to increase the deployment potential of existing AM systems for support-minimising technology. The user not only gets a very capable tool for build-job preparation, but also the opportunity to reduce build time and post-processing costs by significantly reducing material support structures.”

Download Metal AM magazine