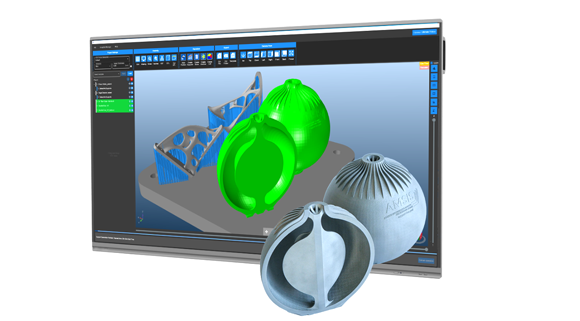

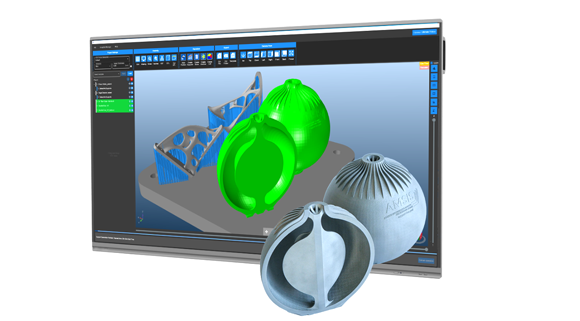

Amsis launches Genesis 3 data and build preparation software

September 12, 2023

Amsis, based in Bremen, Germany, has launched a new version of its data preparation and simulation software, Genesis 3. The software is designed to reduce the need for support structures in overhang areas, optimise component surfaces, and enhance mechanical properties. Genesis 3 is said to allow for complete digital control over the generation process of an additively manufactured component.

The software offers three different automated tools to prepare a build job. The user interface displays all available functions for build job strategies. Genesis 3 also offers material-specific, simulation-based thermal segmentation of down-skins. The software’s simulation-based hatching design provides an optimal hatch orientation and sequence to improve heat balance for every application. Support structures can be generated automatically, with the user receiving a preview of the exposure pattern in various displays.

The central element is a simple, component-specific adjustment of parameters to optimise geometry, surface, and densities. Finally, all construction job parameters can be saved in a template manager to enable a repeatable process. The result is a component with almost no support structures, possibly with overhangs/undercuts of up to 25° depending on the material and part geometry, with specifically influenced mechanical material properties.

Genesis 3 is also said to offer cost advantages in three dimensions. Firstly, manufacturing costs are reduced by using a component structure with fewer support structures. Secondly, construction times and material consumption are minimised. Thirdly, post-processing costs of the AM component are reduced because fewer support structures need to be removed and surface post-treatment can be shortened.

Download Metal AM magazine