AMRC installs new MELD Additive Manufacturing machine

November 3, 2020

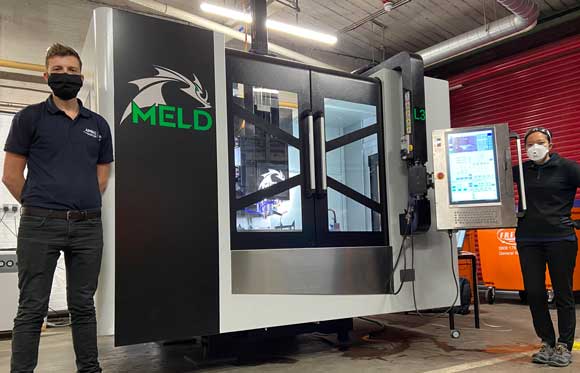

The Advanced Manufacturing Research Centre (AMRC), at the University of Sheffield, South Yorkshire, UK, has installed a MELD L3 metal Additive Manufacturing machine, which MELD Manufacturing Corporation, Christiansburg, Virginia, USA, released in September. The L3 has a build volume of 114 x 58 x 58 cm and a table size of 130 cm x 58 cm.

The AMRC is a world-leading research and innovation institution with more than 120 industrial partners. The University of Sheffield is a part of the larger AMRC group, which is a cluster of centres for industry-focused research and the development of technologies used in high-value manufacturing sectors.

The machine was installed at the AMRC North West facility in Preston, UK, with operator training for technical staff provided by RAM Engineering and Tooling LTD, based in Forfar, Angus, Scotland.

Ian Brooks, AMRC North West Technical Fellow, stated, “Unlike traditional Additive Manufacturing, MELD is a solid state process which means the negative aspects of processing with high temperatures are removed and there is a step change in some of the limitations, such as scalability, residual stress and speed.”