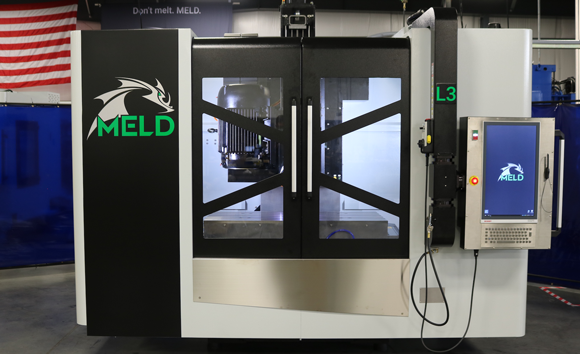

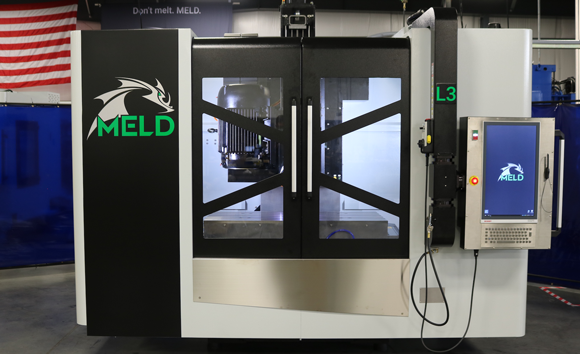

MELD releases new L3 Additive Manufacturing machine

September 15, 2020

MELD Manufacturing Corporation, Christiansburg, Virginia, USA, has released the L3 MELD machine, the latest in its range of metal Additive Manufacturing machines. The L3 has a build volume of 114 x 58 x 58 cm (45 x 23 x 23 in) and a table size of 130 cm x 58 cm (51 in x 23 in).

The L3 machine sits between the larger MELD K2 model, with a build volume of 210 x 110 x 100 cm (83 x 43 x 39 in), and the smaller B8 model offering a build volume of 91 x 30 x 30 (36 x 12 x 12 in).

The open-air operation of the MELD machine is said to make it unique, with simplified requirements for material, usability and operating costs. MELD states that this simplicity extends to safety, only requiring standard manufacturing protective equipment.

“When we look at our customers and what they want to do with the technology it was clear that there needed to be a machine with a platform perfect for both part fabrication and repair,” commented Dr Chase Cox, MELD Manufacturing Corporation Director of Technology.

“The L3 serves that need, offering a tremendous increase in production capability without requiring a larger footprint on the manufacturing floor.”