Ampower adds Simufact Additive to its customer offering

July 12, 2018

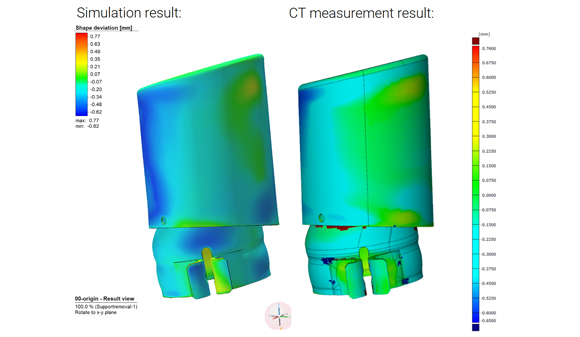

Comparison between simulated and real part deviation of an additively manufactured automotive component (Courtesy Ampower)

Additive Manufacturing consulting firm Ampower, Hamburg, Germany, will partner with Simufact Engineering, an MSC Software company, to offer its customers access to Simufact Additive for the simulation of metal Additive Manufacturing processes. According to the partners, the aim of the cooperation is to increase the use of simulation for AM across the company’s client base, offering targeted support to its customers from the early stage of product development through to optimising production.

Simufact Additive is a scalable process simulation environment which enables Laser Powder Bed Fusion (LPBF) process optimisation with the aim of achieving ‘first time right’ part production. Its features include simulation of all the key AM process steps, including the build process, heat treatment, retrieval from the build plate and removing of support structures, as well as Hot Isostatic Pressing.

Michael Wohlmuth, Managing Director, Simufact Engineering, stated, “Part distortion induced due to residual stresses is one of the biggest challenges in metal-based Additive Manufacturing processes. Simufact Additive helps the user to predict the consequences of residual stresses. Often distortions are compensated accordingly with an adjustment of the manufacturing data, so that the manufacturing tolerances are met and rejects avoided. With Ampower as a partner, we have gained a team of experts in Additive Manufacturing, helping us to further develop our software solution to meet new market needs.”

“Additive Manufacturing for metal components is a technology that is already indispensable in many industries today,” added Dr.-Ing. Maximilian Munsch, Partner and Co-founder of Ampower. “Nevertheless, users are constantly confronted with the high complexity of the process and are looking for solutions to sustainably reduce them. Simufact Additive enables us to detect distortions and part defects even before the actual construction process and to counteract these by targeted optimisation. This helps us to help our customers avoid high costs and time-consuming trials.”