AML3D to produce AM parts for leading Australian energy company

June 16, 2022

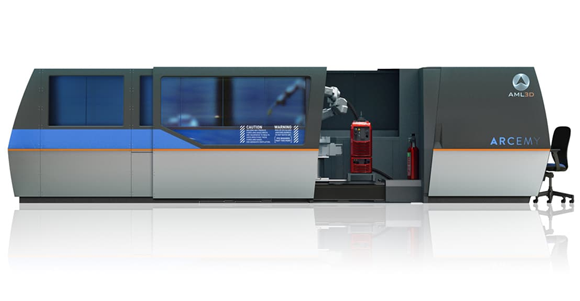

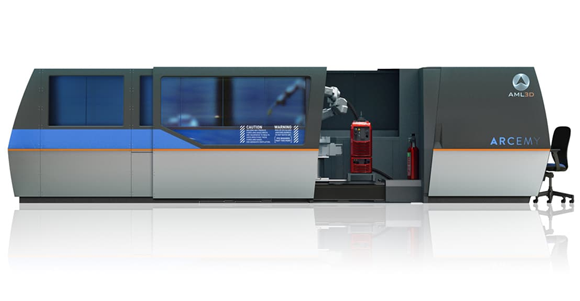

AML3D Limited, Edinburgh, Australia, has become an approved supplier of additively manufactured metal components to a leading Australian energy company. Under the purchase order, the company will use its WAM® technology – also known as Wire Arc Additive Manufacturing (WAAM), a wire-based form of Directed Energy Deposition (DED) – to manufacture components for the energy company’s parts replacement process for existing power generational facilities. AML3D will deliver relevant components on an on-demand basis from its Adelaide facility.

“Entering into this purchase order demonstrates AML3D is delivering against our multi phase growth strategy,” stated Andrew Sales, Managing Director, AML3D. “We identified supplying high-value replacement components to the energy sector as an immediate value driver for the business, and becoming an approved supplier to a major energy provider aligns with that objective.”

The initial purchase order for additively manufactured parts from AML3D is on standard commercial terms and valued at approximately $55,000, which is not material in terms of AML3D’s forecast annual revenue. This initial purchase order includes the manufacture of impellers produced from high-value nickel aluminium bronze material. It is noted as consistent with AML3D’s growth strategy and demonstrates the capacity to produce high-value replacement components for the energy sector.

AML3D will operate a 3D scanning process to initiate the creation of a digital virtual component inventory library using this purchase order to provide a future platform as the energy company progresses through its ongoing parts replacement programme. The creation of this parts library will enable the company to reduce its store of inventories and reduce supply chain risks by providing a reliable and efficient on-demand supply of replacement parts.

Over the coming months, we will work with our customer to undertake a 3D scanning programme of their inventory to build a digital library of parts for future supply,” Sales added. “AML3D looks forward to being a valuable, high-quality and efficient supplier of parts to the energy sector, with materially better sustainability and environmental outcomes compared to traditional component part suppliers.”