AML3D expands US Navy submarine Additive Manufacturing with nickel-aluminium-bronze prototype order

September 19, 2023

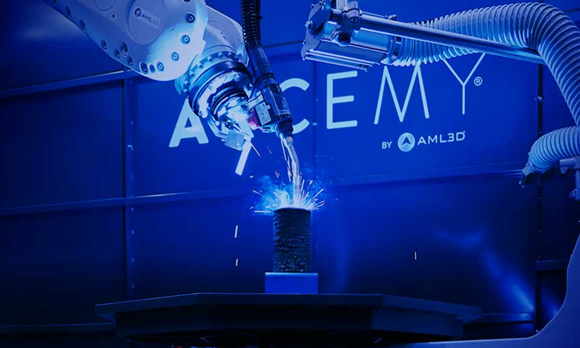

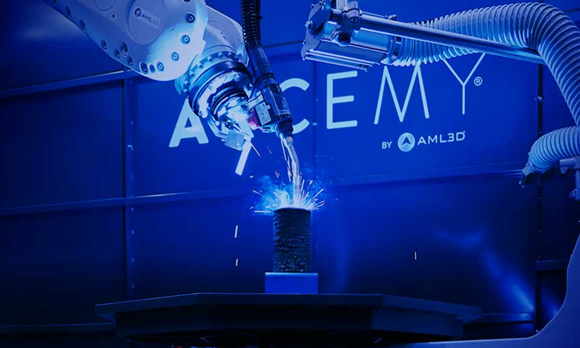

AML3D Limited, headquartered in Edinburgh, Australia, has announced the development of a new prototype nickel-aluminium-bronze (NAB) component to support the US Navy’s submarine programme. The order is for the manufacture of an approximately 1-tonne prototype using AML3D’s proprietary ARCEMY metal Additive Manufacturing technology. The order has been placed by BlueForge Alliance, a nonprofit, neutral integrator that supports the strengthening and sustainment of the US Navy’s Submarine Industrial Base through technology adoption and acceleration.

This prototype component order is valued at approximately AUS $0.60 million ($387,000) and is said to further demonstrate the key role that AML3D can play in supporting the US Navy’s Submarine Industrial Base through the adoption of AM technologies. The manufacturing cycle for the new prototype component is expected to run for a period of twenty-two to twenty-four weeks, and it will be carried out at AML3D’s facility in Adelaide, South Australia.

Successfully fulfilling this new NAB prototype component order could expand the range of US Navy Submarine parts that can be produced using AML3D’s ARCEMY metal AM systems. This follows a recent contract worth AUS $2.02 million ($1.51 million) to develop and manufacture, using metal Additive Manufacturing, a complex, high-demand, non-safety-critical replacement NAB component used in US Navy submarines.

This new order is in line with the company’s strategy to scale up in the US and become a point of need for Additive Manufacturing technology solutions that address supply chain constraints within the US Navy’s submarine programme. The US is the largest Additive Manufacturing market in the world and AML3D’s most important growth market. The company is reportedly confident that additional contracts will be executed in 2023, further expanding AML3D’s ongoing sales to the US defence sector.

“It is exciting to see this expansion of prototype component manufacturing using AML3D’s proprietary ARCEMY technology to support the US Navy’s submarine Industrial base,” stated Sean Ebert, Managing, Director. “This order is another opportunity to demonstrate AML3D’s cost effective, high efficiency, high quality, Additive Manufacturing technology. It is also a great opportunity to demonstrate the key role large scale ARCEMY systems can play within the US defence sector as point-of-need manufacturing solutions with the potential to solve supply chain challenges for the US Navy.”

“AML3D’s US scale up strategy is focused on developing and deepening our long-term, strategic partnership with key stakeholders within the US Navy’s submarine programme. Our ability to deliver contract manufacturing solutions that support ARCEMY systems sales into the US defence sector is an important part of this strategy. This new NAB prototype component order is also timely in the context of the AUKUS Alliance partnership between Australia, the USA and the UK, and the opportunities AML3D may have to access additional defence markets over the medium to longer term,” Ebert concluded.

Download Metal AM magazine