AML3D and NDE showcase metal AM and testing at leading international maritime event

May 4, 2022

AML3D Limited and NDE Solutions, both based in Adelaide, Australia, plan to showcase their metal Additive Manufacturing and testing processes whilst co-exhibiting at the Australian Indo-Pacific 2022 international maritime exposition. Together, the two companies will illustrate how metal AM parts can be validated through rigorous testing and inspection processes. Particularly regarding high-value asset quality of small to large run part manufacturing, replacement components, and upgrades commonly seen in the maritime and defence supply chain and other critical industries such as mining, minerals, oil and gas.

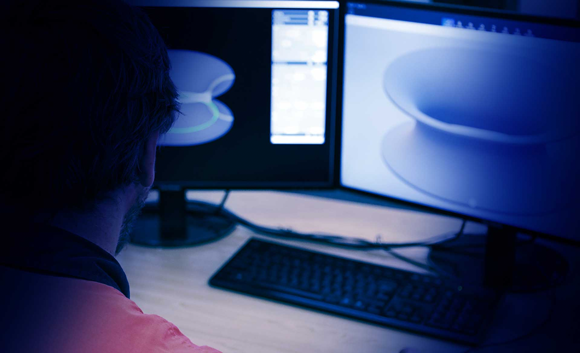

AML3D intends to highlight its patented Wire Additive Manufacturing (WAM®) process, also known as Wire Arc Additive Manufacturing (WAAM), a wire-based form of Directed Energy Deposition (DED). The process enables large scale and novel material components to be additively manufactured faster and more sustainably than traditional casting or billet machining techniques.

The company will display a Panama Chock, similar to the world’s largest additively manufactured shipboard fitting that AML3D manufactured with its WAM process for Keppel Technology and Innovation. Also on show will be the world’s largest registered metal additively manufactured oil & gas piping component. This 940 kg monocoque pipe spool is intended to demonstrate the capability of WAM for high-pressure environments that require manufacturing to a range of specific industry standards.

The release of updated software, WAMSoft® and AMLSoft™, will be another talking point for AML3D. These updated editions are said to feature easier to navigate interfaces, simplifying the path planning and ARCEMY® metal Additive Manufacturing process. Secure remote control has been integrated into AMLSoft™, and remote monitoring is made possible with strategically placed cameras and the industrial Internet of Things.

“We are pleased to have the opportunity to exhibit alongside NDE Solutions,” stated Andrew Sales, Managing Director, AML3D. “Industry collaborations such as ours aid in verifying new technologies, such as our proprietary process, Wire Additive Manufacturing. Our objective is to support and increase Australia’s manufacturing capability with our technology, providing a faster, stronger and greener process when compared to traditional manufacturing methods, which fits well with our key business strategic growth plans.”

For NDE Solutions, Indo-Pacific is seen as an opportunity to share its non-destructive testing (NDT) and inspection solutions with the industry. The company states that its point of difference is the ability to put the client in control of its assets worldwide using augmented reality, robotics and the Internet of Things. The live connectivity of the remote inspection is said to allow for very specialised forms of NDT to be used, enabling improved detection and faster inspections than alternative forms of NDE.

Kimal Singh, Managing Director, NDE Solutions, added, “Now more than ever, Australian businesses need to work together to rebuild our economy and return the value chain onshore. Partnerships with innovative companies like AML3D have huge potential to accelerate sovereign capability. NDE Solutions is pleased to collaborate with AML3D on world-first technologies. This is in line with our mission to pioneer solutions for humankind.”

AML3D and NDE Solutions will be on stand 1C13 throughout the event.