AML3D additively manufactures largest verified oil & gas piping part

November 23, 2021

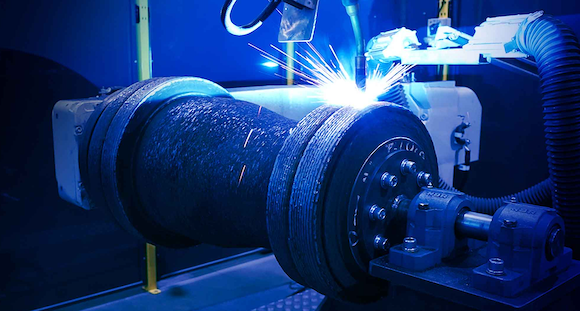

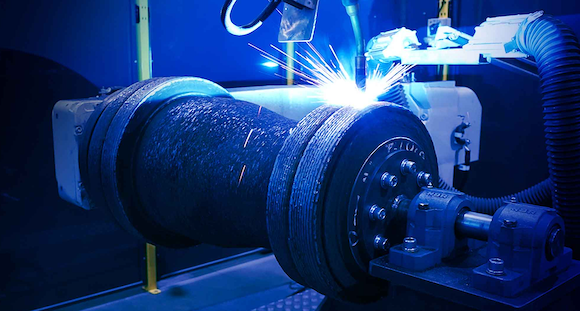

AML3D Limited, Edinburgh, Australia, has additively manufactured what is said to be the world’s largest high-pressure oil & gas piping component to be tested and verified by Lloyd’s Register. The demonstrator component was manufactured as part of AML3D’s internal development programme, showcasing capabilities in the subsea oil & gas sector.

The 940 kg component is a high-pressure piping spool, 850 mm in length, 450 mm in diameter and 41 mm thick. The spool was additively manufactured in one piece using AML3D’s WAM® technology, also known as Wire Arc Additive Manufacturing (WAAM), a wire-based form of Directed Energy Deposition (DED). Using this process allowed for improved material properties using a higher-strength wire feedstock and optimised process parameters, while reducing the manufacturing time from months to just days. The production was done according to the newly released American Petroleum Institute (API) Standard 20S and has met all test acceptance criteria.

The component then underwent industry-standard high-pressure testing, conducted by Trushape Engineering. The spool was pressurised to 34,790 kPa and held for an extended period with no loss of structural integrity. The testing was independently witnessed and verified by Lloyd’s Register. The component also passed the acceptance testing for ASME B31.3, a well-used American standard for these applications

Typically, a high-pressure component of this nature would be found in conditions within the safety-critical systems on oil & gas facilities, which contain hazardous fluids under very high pressures that are highly corrosive, and typically have high-temperature environments.

“AML3D is thrilled with the results from the high-pressure testing witnessed and verified by Lloyd’s Register,” stated Andrew Sales, Managing Director, AML3D. “We now have a high level of interest already shown by participants in the oil & gas sector, and are in discussions with several opportunities. The ability to demonstrate to this sector the capabilities and outstanding test results of our patented Wire Additive Manufacturing process opens the door for far greater application.”