AM Solutions installs its 2-in-1 post-processing machine at UK customer experience centre

December 8, 2023

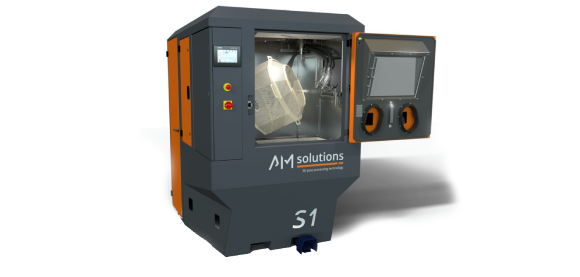

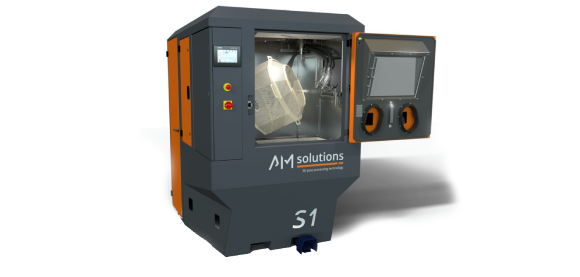

AM Solutions – 3D post processing technology, part of Rösler Oberflächentechnik headquartered in Untermerzbach, Germany, has installed its S1 post-processing unit, for use with parts produced via Powder Bed Fusion (PBF) Additive Manufacturing, in its customer experience centre in Knowsley, Merseyside, UK.

The S1 is able to perform cleaning and surface finishing in one self-contained unit with the same media, in a manual or automatic process. The plug-and-platy machine is also suitable for the surface finishing of de-powdered metal components made from non-reactive metals and is equipped with a blast media conditioning system for optimal and consistent quality of the blasting media. It also features a newly developed air management system which enables fewer deposits in the interior.

“As a company operating in the dynamic area of AM post processing, we are focusing increasingly on volume production,” said Colin Spellacy, Head of Sales at AM Solutions UK. “The S1 which we have just installed in our customer experience centre is one of our 2-in-1 solutions, running two post processing steps in one single machine. This, combined with a higher degree of automation, streamlines the entire process chain and substantially reduces the costs per piece. Such an approach allows us to perfectly fulfil the requirements of customers who are looking for high volume production with 3D printing technologies.”

The S1 reportedly enables the reduction in the processing time for AM parts by over 60% and reduces the need for manual post-processing of often delicate, large and geometrically complex components – often a necessity for companies using AM for volume manufacturing applications.

Spellacy continues, “We invite anyone interested in our post-processing capabilities to visit our customer experience centre in Knowsley. In the centre we can realistically reproduce and test every likely requirement customers may have when post processing AM parts and components. We can ultimately provide you with details of the perfect process solution for your specific applications. We have several printing technologies and post processing solutions in addition to the S1 in the centre, allowing us to demonstrate the solution that best meets your specific requirements.”

AM Solutions’ S1 features improved basket design for optimal distribution and tumbling of parts, and uses a specially developed wear protection lining made of non-staining anti-static polyurethane. It is also ATEX certified and features a media conditioning system for maintaining consistent blast media quality and sizing.

Download Metal AM magazine