AM model shows researchers how earthquakes affect different rock layers

June 1, 2022

A group of researchers have recently published “Seismic wave simulation using a 3D printed model of the Los Angeles Basin” in Scientific Reports. The paper – written by Sunyoung Park of the University of Chicago, Illinois, USA; Changsoo Shin, Seoul National University, South Korea; Younglib Kim, Korea Advanced Machinery; and Robert Clayton, California Institute of Technology – illustrated how the use of Additive Manufacturing and laser techniques can improve the collective knowledge of what happens in the earth’s layers during earthquakes.

Historically, it’s been difficult for scientists to gauge how the ground moves during these events due to the number of variables: the composition of each layer, the area’s geography, and the depth and severity of the earthquakes must all be taken into consideration when trying to predict the outcome of an earthquake.

“We know that you would experience the same earthquake differently if you were in a basin or on a mountain, but predicting or simulating that is really difficult, in part because it’s just hard to get the level of detail you need,” stated Sunyoung Park. “With these 3D models you can get a level of granularity that really helps you see patterns that you wouldn’t otherwise. It’s a really neat technique.”

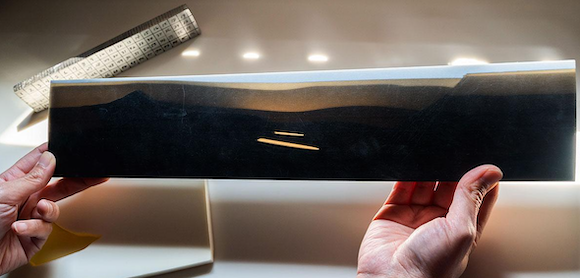

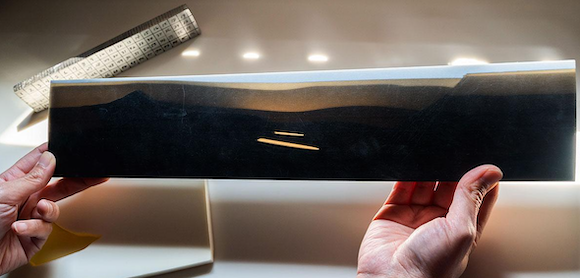

The researchers selected metal Additive Manufacturing to create these models because of its ability to vary density layer by layer, thus simulating different rock striations. Using stainless steel, a model of the earth beneath Los Angeles, California, was additively manufactured on GE Additive’s Concept Laser M2 metal Additive Manufacturing machine at a 1:260,000 ratio. Following this, lasers and lab equipment were used to create & monitor a simulation earthquake in an effort to learn how seismic waves move through different layers. In this study, the researchers focused on the frequency of waves that impact the outcomes.

“This result actually shows that within the basin, the high-frequency waves are more diminished, which is almost exactly the opposite of what was previously thought,” added Park. “It seems to imply that what we have been understanding for low-frequency waves does not hold up for the higher-frequency waves, and that we may need a different framework to understand these shakes.

The paper is available here in full.