Aluminium Materials Technologies and University of Birmingham collaborate to further understanding of A20X aluminium alloy

January 12, 2021

Aluminium Materials Technologies Ltd, Worcester, UK, and the Advanced Materials and Processing Laboratory (AMPLab) at the University of Birmingham, UK, have announced a collaboration to further the metallurgical understanding of additively manufactured high strength, high temperature A20X™ aluminium alloy.

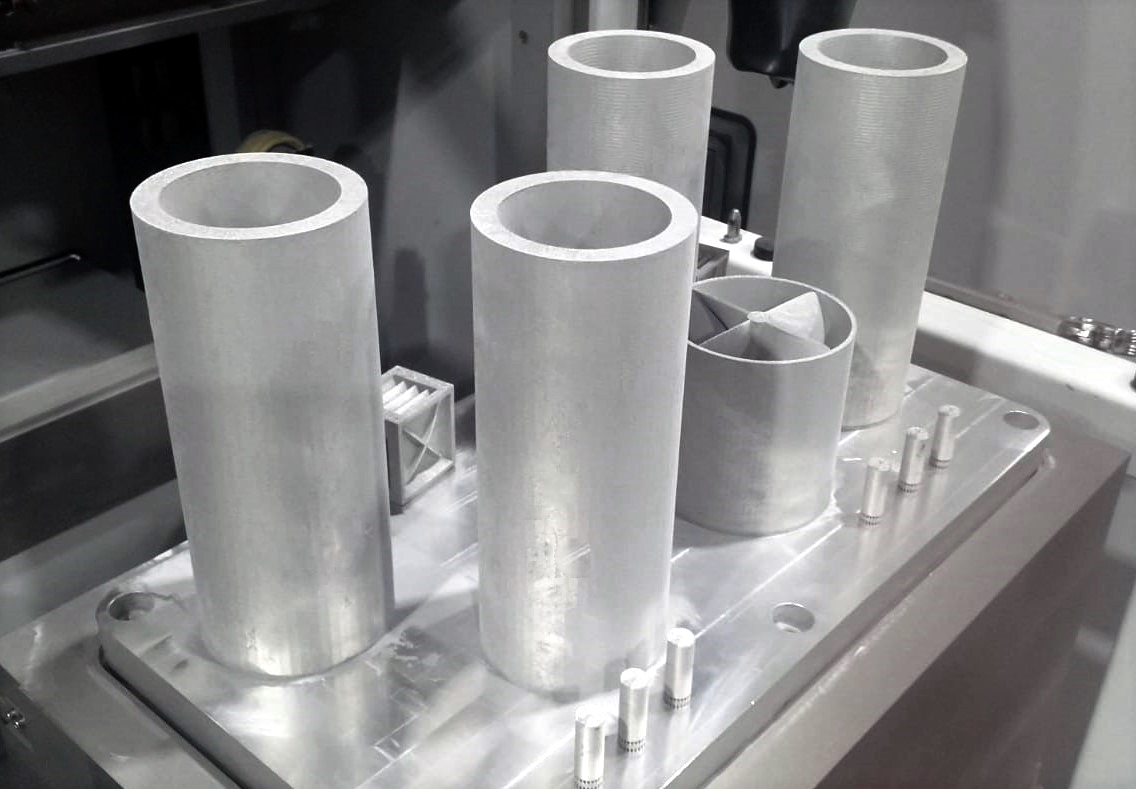

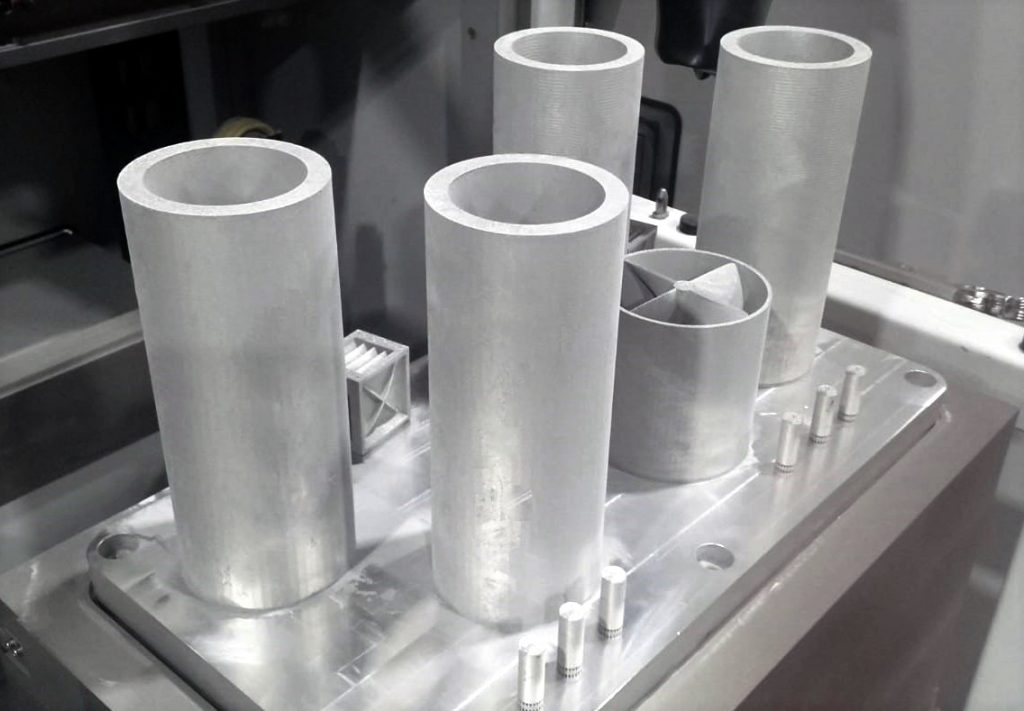

Following a number of successful projects by the university to build sample parts for other interested parties, the two organisations are working together to look further into the characteristic properties of the alloy produced via Laser Beam Powder Bed Fusion (PBF-LB) and Directed Energy Deposition (DED). They are also investigating the effects on changes in composition, heat treatments, and AM process parameters on the properties in additively manufactured components.

A20X has been developed to be a family of patented high-strength aluminium-copper alloys, used mainly in the aerospace and high-end motorsports sectors. The A20X alloy group includes the Metallic Materials Properties Development and Standardisation (MMPDS) approved A205 casting alloy, FIA approved A205/F1 casting alloy, silver free A207 casting alloy, and 2A05 (A205) powder, and 2B05 (A205/F1) powder for PBF-LB AM applications. The highly-refined microstructure, resulting from a unique solidification mechanism, is reported to lead to near fully isotropic properties that provide greater strength, fatigue and thermal characteristics compared to other alloys.

Martin McMahon, Business Development Director for Aluminium Materials Technologies, stated, “A20X has been successfully adopted into fully-qualified production of aerospace components via additive manufacture. The reliability of the A205 alloy has been proven to be more than adequate in high-strength, high-ductility and high-operating temperature applications, so we are now building on our extensive development programmes to create an even greater understanding of the fundamental metallurgy of the AM alloy. We look forward to making further announcements about the findings from this collaboration with such a prestigious research group.”

Moataz Attallah, Professor of advanced materials processing and director of AMPLab at the School of Metallurgy & Materials at Birmingham University, commented, “The University’s experience with this alloy dates back to the early days of its introduction as a metal powder for Additive Manufacturing, and we have carried out many successful projects characterising the physical properties of candidate parts. So now we are working closely with AMT to dig deeper into what makes this alloy so unique, and through our selection of AM tools and vast array of materials characterisation techniques, we are in a great position to make that happen.”