Altair acquires design software for AM startup Gen3D

June 6, 2022

Altair, Troy, Michigan, USA, has acquired Gen3D, a startup founded in 2018 by academics at the UK’s University of Bath, which provides design software for Additive Manufacturing.

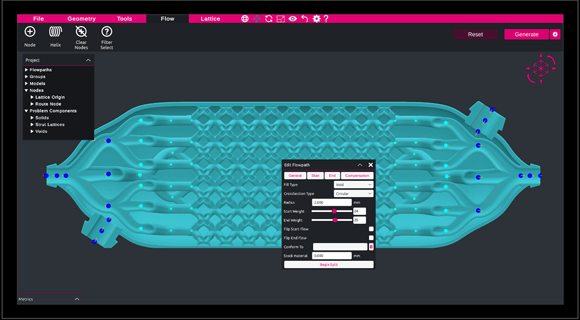

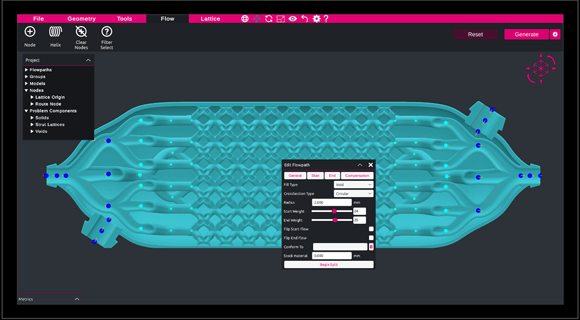

The startup’s technology uses next-generation implicit modelling techniques to create complex geometry not practical with traditional boundary representation (BREP) solid approaches. This allows for components to be designed by specifying the functional requirements for the part (loads, holes for fastenings, keep-out zones, ducts for fluid flow etc). Additionally, the technology automatically filters out component geometries that are likely to cause downstream manufacturing issues.

Gen3D explains that its generative design tool empowers engineers to rapidly create complex designs while minimising the risk of in-situ failures. It is used by design engineers for applications such as energy absorption, heat transfer, filtration, and others across industries such as aerospace, automotive, manufacturing, medical and energy.

The technology will be integrated into Altair Inspire, a family of software products that enables simulation-driven design throughout the entire product development lifecycle, from concept to reality. When used early in the design process, the Inspire technology enables the creation of designs that are focused on both performance and manufacturability and empowers its users to explore, develop, and manufacture high-performance products in a single intuitive development environment.

James R Scapa, founder and chief executive officer, Altair, stated, “In addition to a powerful technology that helps organisations navigate the challenges of design for Additive Manufacturing, the Gen3D team brings deep industry knowledge and experience in advanced additive design techniques such as generative design, topology optimisation, and lattice structure generation.”