AlphaSTAR releases latest version of its GENOA 3DP Additive Manufacturing software

July 7, 2019

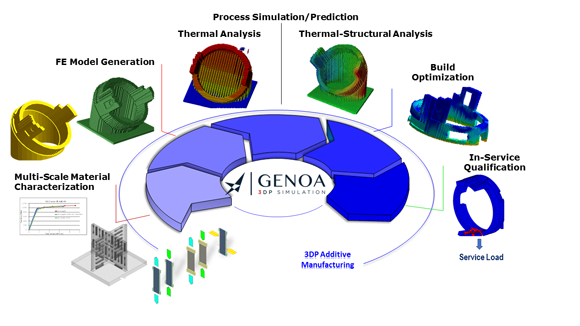

AlphaSTAR has released an updated version of its AM simulation software, GENOA 3DP (Courtesy AlphaSTAR)

AlphaSTAR Corporation, headquartered in Long Beach, California, USA, has released the latest version of its Additive Manufacturing simulation suite, GENOA 3DP. The new release reportedly improves user-friendliness, enhances coupling with commercial FEA solvers, and introduces two new modules: PathCoverage & TMg.

According to the company, GENOA 3DP utilises multi-scale progressive failure analysis to simulate the AM process from material characterisation to process simulation to in-service qualification of an additively manufactured part.

It is said to be able to accurately predict deformation, residual stress, damage initiation and determine voids, warpage, and other manufacturing anomalies seen in AM. Additionally, the tool provides end users with the ability to assess material and process parameter sensitivities, significantly reducing trial and error, material waste and engineering time.

The first new module included in the updated release is the GENOA 3DP PathCoverage: a build path error management tool that visualises and accounts for problematic regions of additively manufactured parts.

The second is the GENOA 3DP TMg: a thermal management tool that accurately predicts thermal history, material states, dynamic evolution of melt-pools and heat affected zones, while identifying stable and unstable zones during the AM process.

AlphaSTAR reports that the updated version of the software also includes the following additional new features:

- Supports external mesh from FEA software

- Design of experiment using surrogate modeling optimisation tool

- Predicts and incorporates temperature dependent additively manufactured material properties

- 30+ step-by-step tutorials

“The AlphaSTAR team has been working diligently to bring users this new and improved version of GENOA 3DP,” commented says Dr Rashid Miraj, Director of Technical Operations at AlphaSTAR. “The newest modules reflect what is needed by industry to continue moving Additive Manufacturing forward. Undoubtedly, this toolset will be a key asset in the way engineers approach and solve the AM challenges that are being faced across the board.”