AIM3D debuts Voxelfill slicing software solution at Formnext 2023

November 3, 2023

AIM3D GmbH, Rostock, Germany, has entered into a development partnership with software company Create it Real, Aalborg, Denmark, to integrate the Voxelfill process as a plug-in into the system technology of the ExAM 255 and ExAM 510 Material Extrusion (MEX) Additive Manufacturing machines.

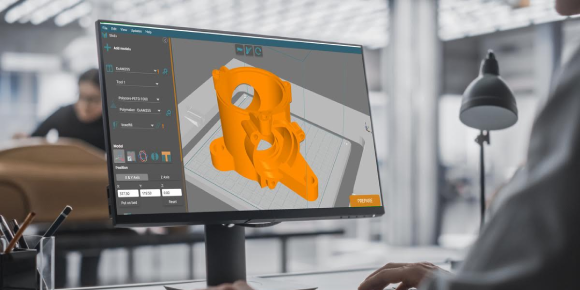

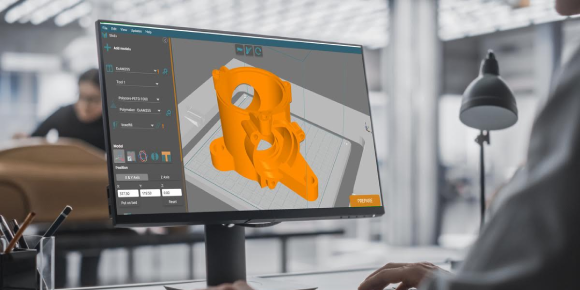

The slicing software solution SlicEx, which is based on Create it Real’s Real Vision Slicer, will, in future, enable users to make best use of AIM3D’s patented Voxelfill technology to overcome inhomogeneous strengths and to achieve selective densities of additively manufactured components made of metals, ceramics, plastics, and fibre-filled plastics.

With Create it Real’s new slicing software solution SlicEx, users are given the opportunity to exploit the potential of Voxelfill in the construction of AM components.

The SlicEx plug-in

With the SlicEx plug-in, users of the AIM3D systems ExAM 255 and ExAM 510 are expected to benefit from the fact that they now have comprehensive access to the AM process with Voxelfill. Furthermore, their input and feedback on the subject of slicers can be passed on via AIM3D directly to the developer Create it Real in order to further optimise the process.

“With the development of Voxelfill, the user now has the possibility to use the unique new process of Voxelfill to improve the z-strength and the printing speed,” stated Clemens Lieberwirth, CTO at AIM3D. “However, these modules are currently still under development.”

Jacob Nissen, CEO of Create it REAL, added, “AIM3D is an ideal partner, backed by a strong academic background and a solid theoretical foundation. Their clear vision aligns perfectly with our capabilities, enabling us to collaborate effectively in achieving their goals.”

The two-stage Voxelfill process at a glance

With the Voxelfill approach, components aren’t created exclusively in layers, but utilise cross-layer filling by using so-called voxels as volume areas. To do this, the component contour is first created as usual, with the basic structure using one or more webs of the extruded material. A lattice pattern is created inside the component which defines the boundaries of the volume elements to be filled.

The Voxelfill strategy then comprises two process stages:

- Generation of a lattice structure: the CEM system repeats this structure up to a defined height of the volume elements, then at this point the previously created voxels are filled by the extruded material extruded;

- When the volume areas are filled, this does not include filling all voxels in one plane; this would again result in a Z direction weakness directly in the ‘seam’ plane. By shifting the volume elements halfway up the voxel, a kind of ‘brick-like bond’ is created in the component, resulting in the yield line being offset. This results in an enormous increase in strength and also improves the elasticity of the components in the Z direction. In addition, the introduced volume elements greatly reduce the printing time for fully filled components and thus significantly increases the cost-effectiveness of the CEM process.

The potential of Voxelfill

Variations of the Voxelfill strategy with the CEM process enable the use of various materials; these hybrid multi-material solutions with different Voxelfill materials and different materials for the contour/structure of the inner walls allow customisable material properties.

Defined component weight, damping properties, elasticity or changes to the centre of gravity can be tailored to the application. By selectively filling only certain volume chambers (selective densities), component properties could be influenced in a targeted manner on the basis of FE simulations. With Voxelfill it is possible to only fill the areas of a component that are absolutely necessary for the flow of forces. As a result, from the outside these components look like conventional parts whilst having the benefits of the AM process, including lightweighting.

Both companies will demonstrate the SlicEx 3D software and the Voxelfill plug-in at Formnext 2023. AIM3D will be in Hall 12.1, E81; Create it Real, 11.0, D68B.

Download Metal AM magazine