Additive Manufacturing Coalition welcomes SLM Solutions as new member

August 26, 2022

The Additive Manufacturing Coalition, Washington, DC, USA, a nonprofit membership organisation for the Additive Manufacturing industry, has announced that SLM Solutions, which has US-based headquarters located in Wixom, Michigan, has joined as a new member. The AM Coalition is a national body committed to supporting its members before the Federal Government and helping to navigate complex legislative challenges to advance the industry.

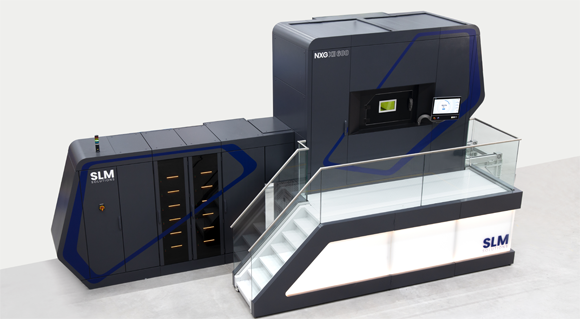

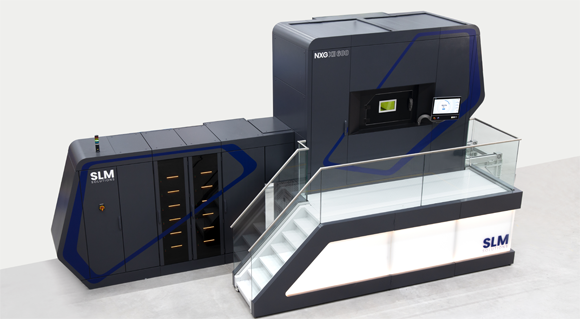

SLM Solutions provides metal Additive Manufacturing solutions, which utilise the Laser Beam Powder Bed Fusion (PBF-LB) process, to the aerospace, aviation, defence, automotive, energy, and health sciences sectors. The company has a metal AM machine install base of approximately 750 machines globally and manufactures some of the quickest metal AM machines available, featuring up to twelve lasers and build rates of up to 1000 cm3/h.

“This key partnership reinforces our commitment to supporting our US customers by aligning with this powerful association to help influence American public policy to accelerate the adoption of AM,” commented Charlie Grace, Chief Commercial Officer at SLM Solutions.

David Cherington, Executive Director of the Additive Manufacturing Coalition, “Having SLM Solutions as a member brings a new voice to our coalition when we’re speaking to decision-makers in Washington, DC about Additive Manufacturing. As the company which invented the selective laser melting process and how that process is expanding the possibilities for AM, SLM Solutions helps to define the possibilities for AM now and into the future.”